2. Cylinder and die are used to feed at the same time, so that the feeding is more accurate, faster, better stability, and basically no stuffing phenomenon.

3. Improving the design of slope track, speeding up the transmission of terminals, the stuffing basically disappeared.

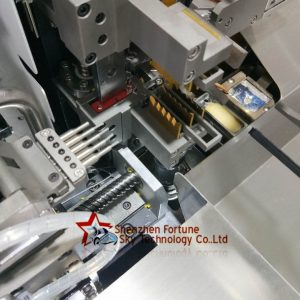

4. 2T ultra-silent wire crimping machine, no noise, safer employees, using card-type mold, easy to unload.

5. Using infrared control, when the track is full of terminals, the vibrating disc stops automatically.

6. Replacing expensive continuous terminals and adopting economical bulk terminals can save cost.

7. It is the best choice for small and medium-sized enterprises to replace singles electric small punches, improve the safety of workers and run at a speed comparable to that of connecting terminals.

Power Source: AC220V/50Hz

Power: Motor 250W / Vibrator bowl: 120W

Net Weight: 130kg

Dimension: 450x860x1360mm

Crimping: 2Ton

Slide Stroke: 30mm

Crimping Frequency: 120times per hour

Closure Height: 26mm

Closure Height Adjust: 10mm

Appropriate Terminal Type: Loose terminal

Production: 7200pcs/hour