Upgrade EV Harness: Auto Wire Cutter & Stripper

Harnessing Automation for Enhanced Efficiency: Automatic Wire Cutter and Stripping Machines in New Energy Vehicle Harness Production

The manufacturing of new energy vehicle harnesses has become heavily reliant on automatic wire cutting and stripping machines.

Mounting concerns over environmental degradation have prompted governments worldwide to adopt new energy policies. With automotive emissions a major contributor, new energy electric vehicles (NEVs) have emerged as a pivotal force in the new economy’s industrial sector. Fueled by government backing, the booming electric vehicle market, with its influx of new players, presents a wealth of opportunities for NEVs and the electric vehicle harness processing industry.

However, processing harnesses for electric vehicles presents a significant challenge for manufacturers. While many electric vehicle manufacturers process their own harnesses, technical complexities often lead to increased costs and extended production cycles. This has created apprehension among many companies regarding in-house electric vehicle harness processing.

So, how can we navigate the processing of harnesses for new energy electric vehicles? Let’s delve into a solution!

Electric vehicle harnesses demand a high level of expertise and precision, making them a challenging category within the harness processing industry. The production technology level of many automotive harness processing factories in China, for example, struggles to meet the stringent quality requirements of electric vehicle harness processing. Since the electric vehicle industry is still in its early stages, there’s a scarcity of wire stripping machines specifically built for processing their unique cables.

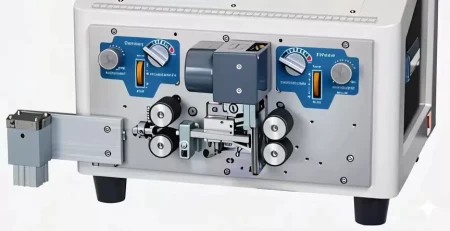

Recognizing the lack of specialized equipment, we’ve pioneered the development of automatic wire cutter and stripping machines specifically designed to meet the diverse production needs of the electric vehicle harness industry. One such innovative solution is the new energy large square wire stripping machine:

This equipment excels at cutting and stripping cables, sheathed wires, and harnesses for new energy vehicles, ranging from 10 to 300 square millimeters in size. This innovative machine streamlines the process into a single step, making it easy for even novice users to operate with a minimal learning curve, while ensuring consistent quality and remarkable efficiency.

Capitalizing on the opportunities presented by the new energy industry, our newly developed automatic wire cutter and stripping machine is a fully automated mechanical device. During processing, it only requires simple harness parameter settings. By automating the process, this machine drastically reduces labor costs and delivers high-precision processing, leading to a significant increase in the production of high-quality finished products compared to traditional methods. Ultimately, it reduces production costs and effectively meets the processing requirements of electric vehicle harness manufacturers.