Efficient Bulk Wire Stripping: Automatic Cuter Machine Guide

Demystifying Bulk Wire Stripping: A Guide to Choosing the Right Machine

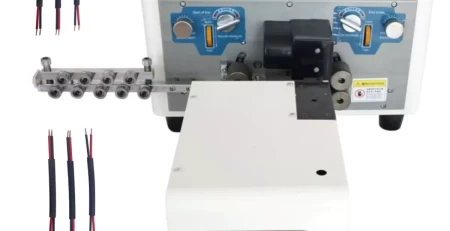

Bulk wire stripping can be a time-consuming and tedious task. Fortunately, automatic wire cutter and stripping machines offer a powerful solution, boosting efficiency and streamlining production processes. However, choosing the right machine can be overwhelming, especially for first-time buyers. This guide aims to demystify the selection process and help you make an informed decision.

Key Factors to Consider:

Speed and Efficiency: Time is money, and the speed of your wire cutter and stripping machine directly impacts productivity. Look for machines that boast an impressive processing rate, typically ranging from 3000 to 6000 cycles per hour. This significantly outperforms manual stripping and allows you to focus on other critical tasks.

Precision Matters: Unlike human hands, machines offer superior precision. When evaluating wire cutter and stripping machines, pay close attention to the stripping error rate, ideally measured in permillage millimeters (thousandths of a millimeter). Choose machines with a minimal error rate to ensure consistent and accurate stripping results.

Consistent Performance: A reliable wire cutter and stripping machine should consistently deliver high-quality results. Look for machines that can produce wires with exact lengths and clean, professional-looking finishes, eliminating any inconsistencies or imperfections.

Experience and Reputation: Choosing a reliable manufacturer is crucial. Opt for established companies with a long history (ideally over a decade) in the industry. Such manufacturers often incorporate cutting-edge technology, proven production methods, and ensure consistent machine quality.

Reliable After-Sales Support: Even the most dependable machinery requires occasional maintenance or troubleshooting. Choose a manufacturer known for responsive and proactive after-sales support. This ensures you have access to technical assistance when needed, minimizing production downtime.

Empowering Efficiency:

By carefully considering these key factors, you can select a wire cutter and stripping machine that perfectly aligns with your production needs. This investment will significantly enhance your efficiency, improve product quality, and allow you to focus on more strategic operations. Remember, choosing the right machine is the first step towards becoming a master of bulk wire stripping.

Find expert wire stripping machine technical resources on our specialized page.