Optimize harness machine performance: faster, safer operation & extended lifespan.

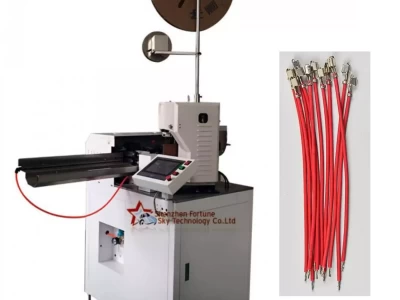

Reduce Errors: Double-Ends Chain Terminal Crimping Machine

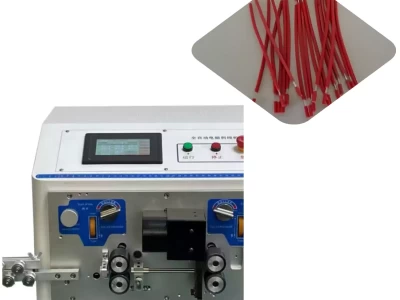

The Double-Ended Advantage: Expanding Efficiency with Automatic Chain Terminal Crimping The automatic double-ends chain terminal crimping machine is rapidly transforming industries reliant on efficient and dependable wire processing. This innovative technology automates the process of attaching terminals to both ends of wires or cables simultaneously, offering significant advantages over traditional manual methods. Let's delve into the diverse applications of this technology across various sectors: 1. Unleashing Production Power in Wire and Cable Manufacturing: For the fast-paced world of wire and cable manufacturing, efficiency...