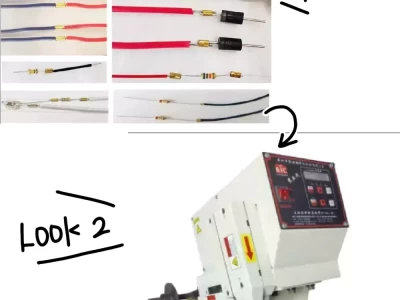

Optimize harness machine performance: faster, safer operation & extended lifespan.

Operation Manual for Silent Terminal Crimping Machine and Common Troubleshooting Methods

I. Pre-Operation Debugging of the Silent Terminal Crimping Machine (Ultra-Silent Terminal Crimping Machine) Die Height Adjustment: Loosen the punch tightening screw. Use a small round rod to adjust the adjustment screw (there are six equally spaced holes around the circumference). Turn clockwise to raise and counterclockwise to lower (each hole represents a change of 0.25 mm). Adjust the punch to the appropriate position, then tighten the punch tightening screw (i.e., adjust the crimping height for the wire core). Adjustment of the Difference...