Optimize harness machine performance: faster, safer operation & extended lifespan.

Vibrating Feeder Not Working? A Quick Troubleshooting Guide!

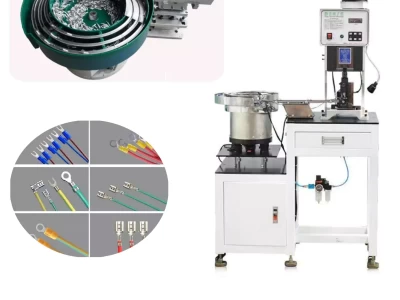

Vibrating Feeder Not Working? A Quick Troubleshooting Guide! Is your vibratory feed terminal crimping machine's vibrating feeder giving you trouble? Don't worry, we've got you covered! This guide will help you quickly diagnose and fix common issues, so you can get back to work faster and more efficiently. When your vibrating feeder decides to take a break, it can be frustrating. But fear not! Let's break down the potential causes and solutions. Important: Incorrect troubleshooting can damage your machine, so please follow these...