Wire Stripping Made Easy! Master Your Auto Tool

Fully Automatic Wire Cutting and Stripping Machines vary in price depending on the specific wire harness being processed.

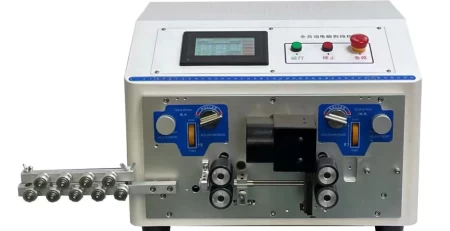

A Fully Automatic Wire Cutting and Stripping Machine refers to a machine that removes the plastic outer covering from wires and separates it from the metal core. In this era of automation and intelligence, automatic wire stripping machines are the most widely used mechanical equipment in the wire harness processing industry. However, many people are not particularly familiar with the operation of automatic wire stripping machines.

The working principle of an automatic wire stripping machine involves the transportation of wires between the input and output wheels, and then the required processing functions of the wire harness are completed through the knife assembly. Let’s explain the operation principle of Fully Auto Wire Stripper in detail.

1. Output Wheel

The Output Wheel transports wires and strips the wire ends. However, it has limitations when handling short wires (typically less than 50mm). In such cases, the Output Wheel Lift Knob must be set to the “u” (up) position to prevent ineffective stripping.

Key Functions:

Transports wires toward the end-stripping mechanism.

Strips insulation from wire ends (except for very short wires).

Requires manual adjustment for short wire stripping.

2. Input Wheel

The Input Wheel feeds wires into the machine and strips the wire heads. Its functionality varies depending on the wire length and stripping requirements.

Operational Modes:

Short Wires (Less than 50mm): Strips both the wire heads and ends.

Mid-Length Wires: Capable of stripping multiple sections along the wire (middle stripping function).

Key Functions:

Ensures smooth wire feeding into the machine.

Performs head stripping and, if needed, mid-length stripping.

3. Input Wheel Pressure Adjustment Knob

Proper pressure adjustment ensures efficient stripping without damaging the conductor.

Adjustment Guidelines:

Increase Pressure: Turn clockwise after pulling out the knob (for harder insulation).

Decrease Pressure: Turn counterclockwise after pulling out (for softer insulation).

Considerations:

Adjust based on insulation strength—higher pressure for tough materials, lower for easier stripping.

4. Input Wheel Gap Adjustment Knob

The gap between the input wheels must match the wire thickness to prevent slippage or crushing.

Adjustment Guidelines:

Increase Gap: Turn the knob upward (for thicker wires).

Decrease Gap: Turn the knob downward (for thinner wires).

Best Practices:

Ensure the wire fits snugly without excessive compression.

5. Output Wheel Gap Adjustment Knob

Similar to the input wheel, the output wheel gap must be adjusted based on wire diameter.

Adjustment Guidelines:

Increase Gap: Turn the knob upward (for thicker wires).

Decrease Gap: Turn the knob downward (for thinner wires).

Best Practices:

Maintain consistent pressure to avoid wire deformation.

6. Input Wheel Lift Knob

This knob facilitates wire threading by lifting the input wheel.

Operational Steps:

Threading Wire: Turn clockwise to lift the wheel for smooth insertion.

During Operation: Turn counterclockwise to lower the wheel and secure the wire.

Key Benefit:

Prevents wire misalignment during feeding.

7. Output Wheel Lift Knob

This knob assists in removing the stripped wire from the machine.

Operational Steps:

Removing Wire: Turn counterclockwise to lift the wheel for easy extraction.

During Operation: Turn clockwise to lower the wheel and maintain tension.

Short Stripping Mode: Keep the wheel lifted (“u” position).

Key Benefit:

Ensures smooth wire ejection without tangling.

8. Output Wheel Pressure Adjustment Knob

Controls the gripping force of the output wheel.

Adjustment Guidelines:

Increase Pressure: Turn counterclockwise after pulling out (for tough insulation).

Decrease Pressure: Turn clockwise after pulling out (for softer insulation).

Considerations:

Adjust based on stripping difficulty—higher pressure enhances grip on hard-to-strip wires.

9. Knife Assembly

The Knife Assembly is responsible for cutting and stripping insulation.

Key Functions:

Cutting: Trims wires to the desired length.

Stripping: Removes insulation from wire heads and ends.

Operational Tips:

In standby mode, fully open both upper and lower blades to allow smooth wire passage.

Ensure blades are sharp and properly aligned for clean cuts.

Conclusion

Properly adjusting and operating a wire stripping machine significantly improves efficiency and strip quality. By understanding each component—such as the input/output wheels, pressure and gap adjustments, lift knobs, and knife assembly—users can optimize performance for different wire types and stripping requirements. Regular maintenance and correct settings ensure consistent, high-quality results in electrical and wiring applications.

This guide serves as a comprehensive reference for both beginners and experienced technicians working with wire stripping machines.

Find expert wire stripping machine technical resources on our specialized page.