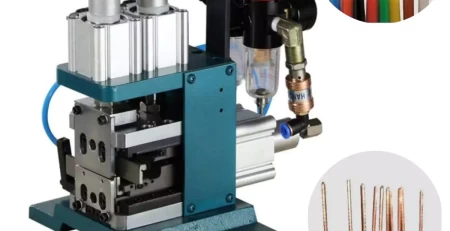

How to Extend the Lifespan of an Automatic Wire Cutter and Stripping Machine

How to Extend the Lifespan of an Automatic Wire Cutter and Stripping Machine

Proper Operation: Operators should undergo professional training and strictly follow the operation manual. For instance, during startup and shutdown, adhere to the correct sequence to prevent sudden starts and stops from shocking internal components. Ensure that wires are placed correctly and fed steadily during operation to avoid obstructions or component damage caused by improper wire placement.

Regular Maintenance:

- Cleaning: Regularly clean the entire automatic wire cutter and stripping machine, including the exterior, feed inlet, outlet, and internal components like blades and transmission parts. For example, conduct weekly external cleaning using a clean, damp cloth to prevent dust and debris accumulation that could affect heat dissipation and performance. Perform monthly internal cleaning to carefully remove wire scraps and dirt from blades and transmission parts.

- Lubrication: Regularly apply the appropriate amount of lubricant to critical transmission components to maintain smooth operation. For example, apply specialized lubricant to transmission shafts, gears, and other parts monthly to reduce friction and wear.

- Blade Maintenance: Regularly inspect blades for wear and promptly sharpen or replace them as needed. Depending on usage frequency, inspect blades every 50 to 100 hours. Replace blades when they exhibit significant wear or if stripping quality declines.

- Parameter Adjustment: Accurately adjust machine parameters, such as stripping speed and cutting depth, based on wire specifications and materials. Avoid excessive parameter settings that could overload the machine and accelerate component wear. For example, reduce stripping speed and cutting depth for thinner wires to lessen stress on the machine.

Environmental Control:

- Place the machine in a dry, well-ventilated environment to protect electronic components and mechanical parts from humidity and high temperatures. For example, maintain relative humidity between 40% and 60% and temperature between 10°C and 35°C.

- Keep the surrounding area clean to prevent debris accumulation that could affect heat dissipation and normal operation.

Quality Control:

- Use high-quality wires to prevent additional wear caused by wire quality issues such as impurities or uneven hardness.

- Regularly inspect and calibrate the machine to ensure all functions are operating correctly and meet accuracy requirements. For instance, conduct a comprehensive inspection and calibration every six months to adjust parameters and components for optimal performance.

Prompt Troubleshooting:

- Stop using the automatic wire cutter and stripping machine immediately if any malfunctions or abnormalities occur and conduct a thorough inspection and repair. For example, if the machine produces abnormal noise or vibration, promptly identify the cause, which could be loose components, damaged blades, or transmission part failures, and repair or replace damaged parts as needed.

- Address minor faults and issues promptly to prevent them from escalating into more serious damage. For instance, promptly replace worn wires, connectors, and other components to prevent electrical faults that could shorten the machine’s lifespan.

Find expert automatic wire cutter stripper technical resources on our specialized page.