Garment Label Cutting Machine: Cutter Wear Explained

Demystifying Cutter Wear in Ultrasonic Garment Label Cutting Machines

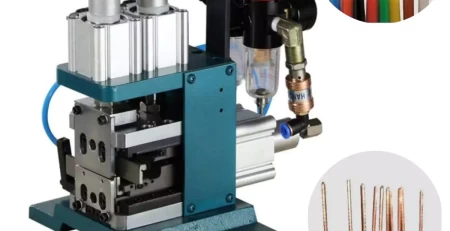

The Ultrasonic Garment Label Cutting Machine produces flawlessly finished labels, free from fraying or discoloration. This superior quality comes at a cost, however, as the cutting knife experiences relatively rapid wear. Let’s delve into the science behind this phenomenon.

Ultrasonic Fusion: Powering Precise Cuts

The Ultrasonic Garment Label Cutting Machine utilizes a unique technology that combines ultrasonic welding with conventional cutting techniques. During operation, the ultrasonic generator transmits high-frequency vibrations through a transducer to the welding head. This energy causes the head to vibrate intensely, creating friction as it interacts with the cutting blade. Compressed air precisely positions the blade against the vibrating head, resulting in a clean and precise cut.

Beyond Straight Cuts: Adaptability and Efficiency

While primarily used for cutting ribbons and webbings, these machines offer versatility. Straight blades are standard, but customizable shapes like bevels, trapezoids, and dovetails are achievable. Additionally, computer-controlled programming allows for adjustments to cater to various materials and cutting requirements.

Understanding the Cause of Cutter Wear

The ultrasonic cutting process relies on high-speed friction and blade pressure to achieve a clean cut. Even with the cushioning effect of the material being cut, perfect contact between the blade and the ultrasonic steel die is impossible. This constant high-frequency (over 200,000 vibrations per second) vibration and friction under pressure lead to inevitable wear on the cutting blade.

Furthermore, the slight delay in compressed air actuation can exacerbate wear. During the cutting cycle, the blade’s inertia can cause it to continue vibrating and rubbing against the welding head even after receiving the “stop” signal. This emphasizes the importance of maintaining optimal air pressure settings for accurate blade positioning.

Beyond Friction: The Role of Material Hardness

High-frequency vibrations exceeding 20 kHz contribute to cutter wear. While crucial for precision, these vibrations also create a grinding effect on the blade. The ultrasonic welding head itself is constructed from high-grade, heat-treated alloy steel with exceptional hardness (around 60 Rockwell or higher). To withstand potential contact with the welding head, the cutting blade must also be crafted from high-quality tool steel.

Maximizing Machine Performance

By understanding the factors that cause cutter wear, you can optimize the lifespan and performance of your Ultrasonic Garment Label Cutting Machine. This knowledge empowers you to appreciate the intricate technology behind its operation and make informed decisions regarding blade maintenance and replacement.