A Companion Guide to Auto Wire Stripping Machine Accessories

Optimizing Performance A companion to Automatic wire Stripping Machine Accessories

Your automatic wire stripping machine represents a foundation of effective wire processing. still, unleashing its full eventuality can be achieved by using a range of essential accessories. This companion explores these factors and their part in maximizing your machine’s capabilities.

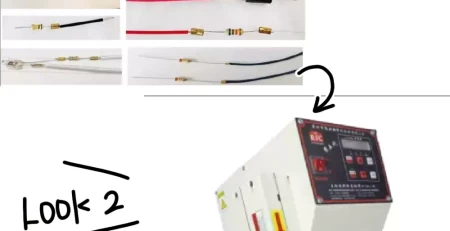

Essential Accessories for Precision Stripping

wire Feeding Roller This comber plays a critical part. It guides and feeds the wire head for stripping, enabling single and multi-stage stripping with exceptional perfection.

Wire Outlet Roller Responsible for smooth wire tail junking, this comber ensures effective wire handling throughout the stripping process. For short cables, acclimate the “ wire outlet comber lifting clump ” to the “ U ” position for optimal performance.

Fine- Tuning Wire Processing

wire Feeding Roller Clearance Adjustment Knob This clump allows you to precisely acclimate the concurrence between the wire feeding comber and the wire itself. Rotate it overhead to increase concurrence for thicker cables, or down for thinner cables.

Pressure Adjustment Knob of Wire Feeding Roller The pressure applied by the wire feeding comber should be acclimatized to the strength of the wire’s sequestration. Turning the clump clockwise increases pressure( suitable for tougher sequestration), while turning counter-clockwise reduces it( for delicate sequestration).

wire Feeding Roller Lifting Knob This clump facilitates smooth wire threading by raising the wire feeding comber. During operation, lower the comber by turning the clump counter-clockwise.

Optimizing wire Affair

Clearance Adjustment Knob of Wire Outlet Roller analogous to the wire feeding comber, this clump adjusts the concurrence between the wire outlet comber and the wire. Rotate it overhead for thicker cables and down for thinner bones .

Pressure Adjustment Knob of Wire Outlet Roller Control the pressure applied by the wire outlet comber grounded on the wire’s sequestration strength. Turn the clump counter-clockwise to increase pressure for further robust sequestration, or clockwise to drop it for further delicate accoutrements .

Wire Outlet Roller Lifting Knob This clump assists in reacquiring finished cables. Rotate the clump counter-clockwise to raise the wire outlet comber for easy junking, and clockwise to lower it back into operating position.

Tool Holder Assembly This assembly houses the slice and stripping blades( both head and tail). When shutting down the machine, insure the upper and lower blades are completely open to avoid gumming wire passage through the knife.

unleashing effectiveness

By understanding and effectively exercising these accessories, you can significantly enhance your automatic wire stripping machine’s capabilities. This enables you to achieve precise and effective wire slice and stripping results, maximizing your machine’s performance and eventually optimizing your workflow.

Find expert wire stripping machine technical resources on our specialized page.