How to Set Parameters for Automatic Wire Cutting Stripping Terminal Crimping Machines

Debugging Methods for Automatic Wire Cutting Stripping Terminal Crimping Machines

I. How to Set Parameters for Automatic Wire Cutting Stripping Terminal Crimping Machines

As an automated equipment used in the production of electrical connectors, the proper parameter settings of the Automatic Wire Cutting Stripping Terminal Crimping Machine are crucial for enhancing production efficiency and product quality.

First, adjusting the pressure parameters is key. Depending on the material and specifications of the workpiece, the pressure should be appropriately increased or decreased to ensure the stability of the connection between the terminal and the workpiece.

Second, controlling the speed parameters directly impacts production efficiency. Setting a reasonable speed ensures both product quality and improved production efficiency.

Optimizing the position parameters is equally important. It ensures the accurate insertion of terminals into the workpiece, enhances connection quality, and reduces the defect rate.

Adjusting the cycle time parameters requires balancing production speed with quality requirements to avoid inefficiency or product defects caused by excessively long or short cycles.

By comprehensively considering these parameters, the production efficiency and product quality of the Automatic Wire Cutting Stripping Terminal Crimping Machine can be effectively improved.

II. Debugging Methods for Automatic Wire Cutting Stripping Terminal Crimping Machines

When debugging the Automatic Wire Cutting Stripping Terminal Crimping Machine, start by checking for any abnormal noises. If any are detected, a professional technician should assess whether repairs are necessary.

The installation of blades must be performed by specialized technical personnel. Ensure that the blades match the specifications of the terminal machine before installation, and conduct a manual swing test.

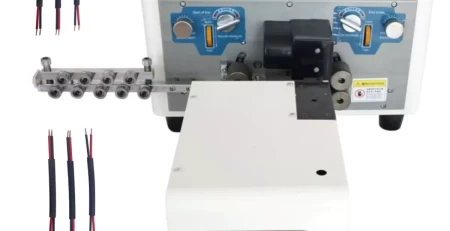

Inspect the feeding system to ensure terminals can pass through smoothly. Adjust the feed pressure plate and manually test whether the feeding position is appropriate. If issues such as material sticking or skipping occur, resolve them by adjusting the regulating lever.

Test the tensile strength to ensure it meets standards. After debugging, perform a tensile test and make adjustments until the standard value is achieved.

Finally, conduct a full-process test to ensure product compliance before proceeding with mass production. Operators should regularly check for issues such as terminals being coated with adhesive or hanging at the neck, and perform a pull-off test once every hour.