Reasons for Inaccurate Cutting in Automatic Wire Cutting Stripping Machines

When using an Automatic Wire Cutting Stripping Machine, you may encounter situations where the cutting length is inaccurate. Today, we will briefly analyze the reasons why an Automatic Wire Cutting Stripping Machine might cut inaccurately.

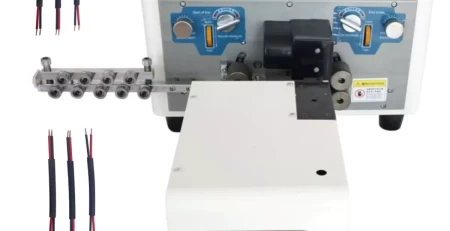

- The wire pressing wheel is slipping.

- The wire pressing wheel is not tightened sufficiently.

- The screws on the internal synchronous pulley of the machine are loose.

- The internal synchronous belt of the machine is worn.

- Loose screws on the wire pressing wheel cause insufficient pressure.

- The screws connecting the motor and the synchronous pulley are loose.

- The motor driver is faulty.

In addition to the points above, the issue could also be related to the machine’s own performance. For example, errors caused by setting a length that is too long, or during multi-stage stripping, instability and low accuracy in strip length can result from factors like excessive spacing between strips, the wire’s adhesion being too high, or too many strip segments.

When the Automatic Wire Cutting Stripping Machine exhibits inaccurate cutting, you can troubleshoot based on the points listed above or contact the equipment supplier for repair as soon as possible to avoid affecting production schedules. That’s all for today.