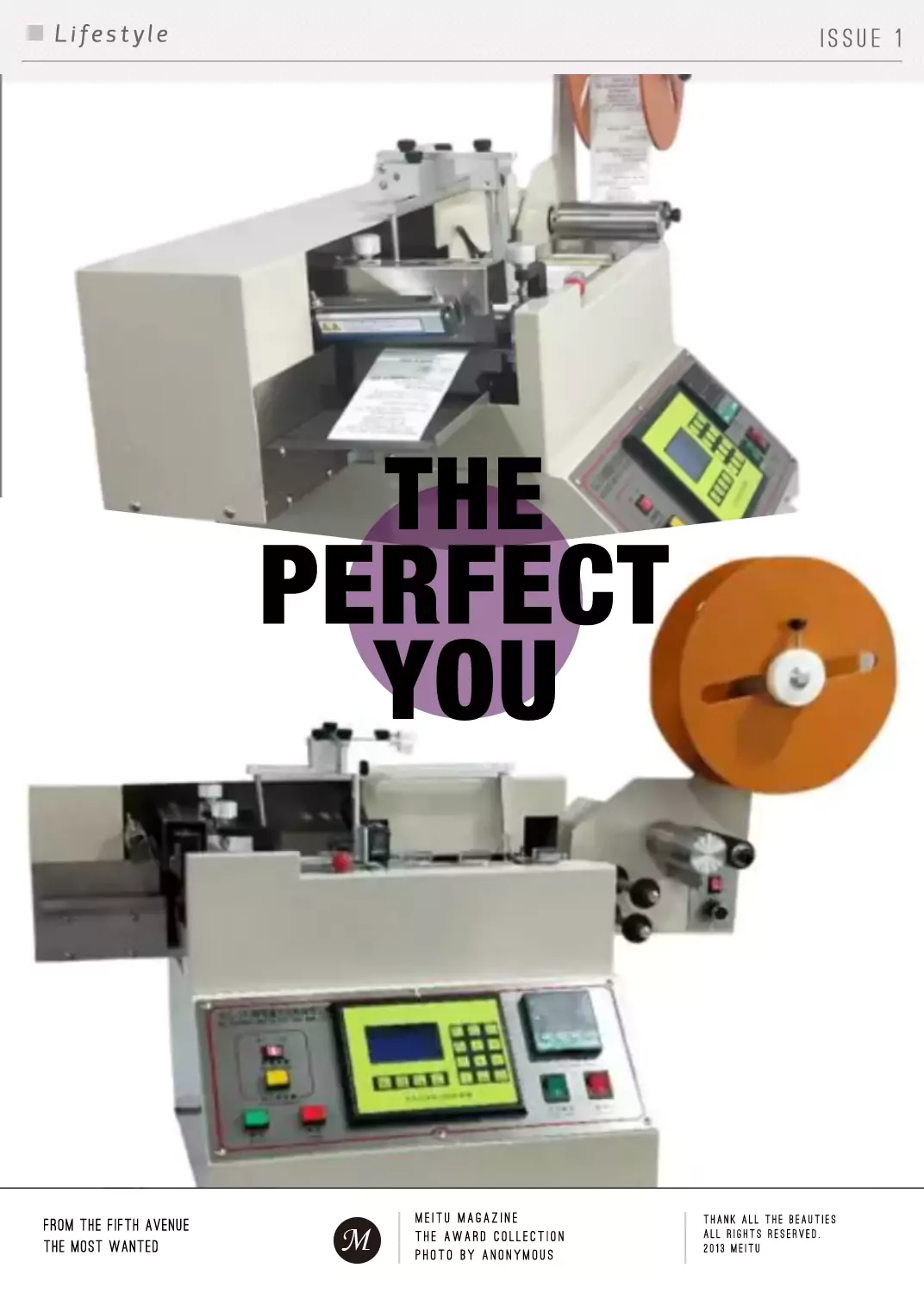

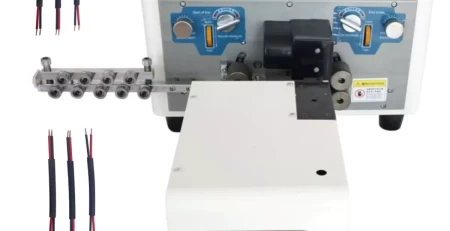

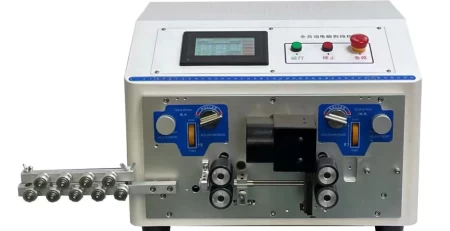

Troubleshooting Common Issues with Cold and Hot Knife High-Speed Label Cutting Machines with Vision System

A Cold and Hot Knife High-Speed Label Cutting Machine with Vision System utilizes ultrasonic technology to cut labels and is widely used in industries such as packaging and printing. These machines may encounter some common malfunctions during operation. Below are some potential issues and their solutions:

1. Incomplete Cutting or Uneven Edges

Possible Causes: The cutting die may be worn, or the settings might be incorrect.

Solutions: Inspect and replace the cutting die; adjust the parameters of the ultrasonic generator (e.g., frequency, power) to suit different material requirements.

2. Excessive Noise During Machine Operation

Possible Causes: This could be due to loose mechanical components or damaged bearings.

Solutions: After stopping the machine, carefully check if all connecting parts are tightened, and repair or replace any problematic components found.

3. Unstable Ultrasonic Output

Possible Causes: This is usually caused by power supply voltage fluctuations, transducer aging, or similar factors.

Solutions: Ensure the equipment receives a stable and reliable power supply; regularly check the transducer’s condition and replace it if necessary.

4. Overheating Leading to Shutdown

Possible Causes: Prolonged operation can cause the internal temperature to rise above the safe range, triggering a protection mechanism that automatically shuts down the machine.

Solutions: Increase cooling facilities, such as fans; maintain a good ventilation environment; reduce continuous working hours and allow for appropriate rest periods.

5. Control System Malfunction

Symptoms: The control panel is unresponsive or displays abnormal information.

Recommended Action: First, try restarting the system to see if it returns to normal; if the problem persists, professional technicians will be needed for diagnosis and repair.