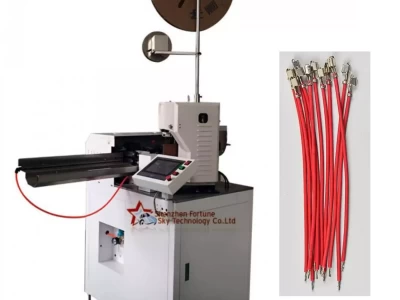

Keep Chain Terminal Crimping Smooth:Maintenance Guide

Troubleshooting Continuous Punching Faults in Chain Terminal Crimping Machines This guide addresses troubleshooting steps for continuous punching faults encountered in chain terminal crimping machines. By following these procedures, you can effectively diagnose and resolve the issue, minimizing downtime and ensuring smooth operation. 1. Foot Pedal Inspection: The foot pedal is a critical component that initiates the crimping process. Begin by checking for any visible signs of damage on the foot pedal itself or the connecting wires. Additionally, verify whether the connection between the...