Ensure distortion-free terminal crimping with our expert tips on operation, maintenance, and equipment selection from trusted brands.

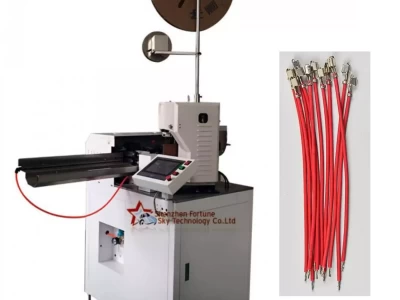

No Distortion! Benchtop Terminal Crimping Machine Guide

No Distortion! Benchtop Terminal Crimping Machine Guide I. Issues with the Benchtop Terminal Crimping Machine Itself Leading to distortion 1.1 inadequate Pressure Acceptable pressure is necessary for the benchtop terminal crimping machine to securely fix the terminal. inadequate pressure can beget the terminal to lose its obsession, performing in distortion. 1.2 Inordinate operation: Dragged operation of the benchtop terminal releasing machine can lead to dropped releasing effectiveness due to disunion and wear, performing in terminal distortion. 1.3 Indecorous material operation: Poor quality or indecorous...