Cable Angle Bender Woes Solved! Fix Faulty Clamps Today!

Cable Angle Bender Woes Solved! Fix Faulty Clamps Today!

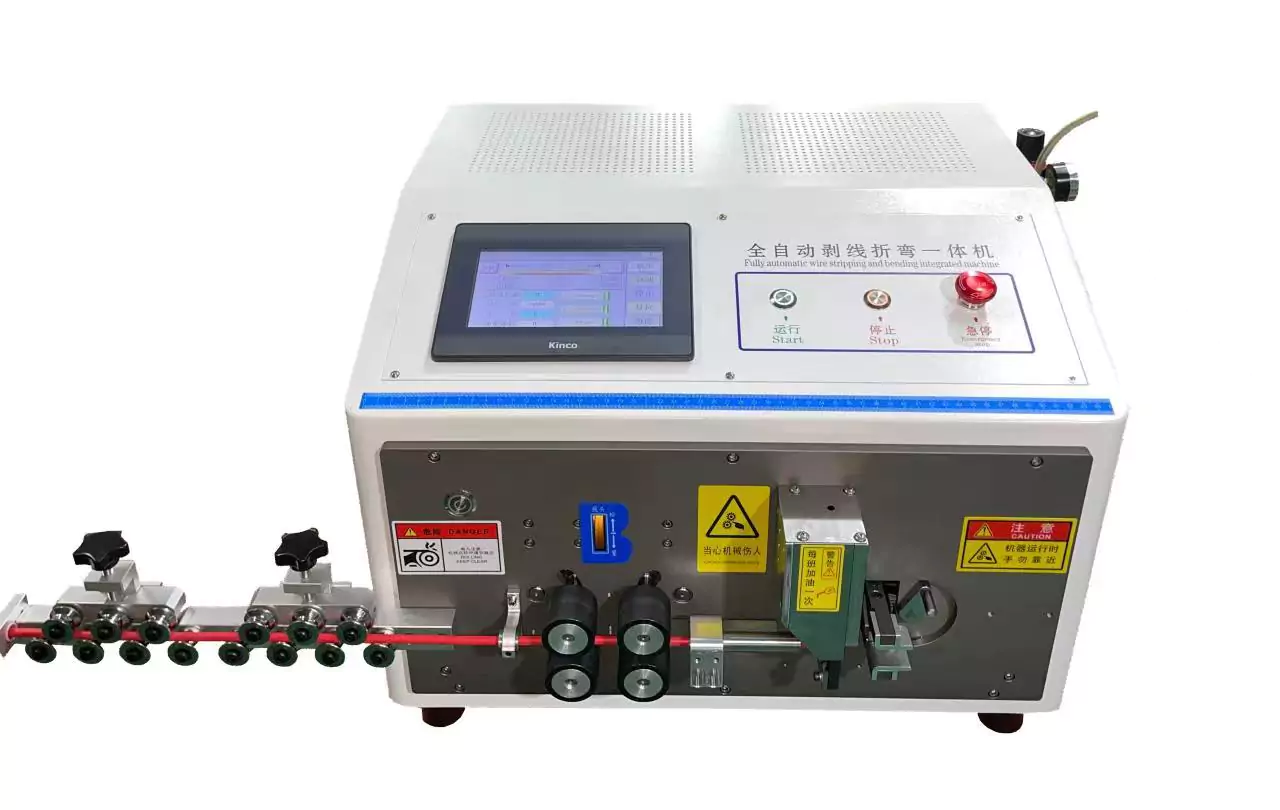

Automatic cable stripping angle bending machines (cable benders) are workhorses in the wire processing world. But even the most reliable machines can experience occasional hiccups, like a clamp failing to grip the cable properly. This can lead to uneven stripping, inaccurate bending angles, and ultimately, production delays. Here, we’ll explore the common culprits behind a faulty clamp and offer solutions to get your cable bender back in top form.

Understanding the Grip: Why Clamps Fail

There are several reasons why a clamp might not be gripping cables effectively:

Size Mismatch: The most common culprit is simply using the wrong size clamp for the cable diameter. Imagine trying to hold a needle with a pair of pliers! If the clamp opening is too large for the cable, it won’t be able to secure it tightly.

Worn Surfaces: Over time, the gripping surfaces of the clamp can wear down due to friction. This wear and tear reduces their ability to hold onto cables firmly.

Internal Wear and Tear: Just like the outside, the internal components of the clamp, such as springs or sliders, can also wear out. When these components become worn or damaged, they can’t apply the necessary clamping force.

Control System Hiccups: In rare instances, a malfunction in the machine’s control system could be causing the clamp to operate incorrectly.

Restoring the Grip: Solutions for Secure Clamping

Here’s what you can do to ensure your cable bender maintains a firm grip on your cables:

Adjust the Clamp Size: If the clamp opening seems too large, consult your user manual for instructions on adjusting the clamp settings. This might involve adjusting specific settings on the machine or using dedicated adjustment tools.

Replace Worn Clamps: For severely worn clamps, replacement is the best solution. Choose a replacement model specifically designed for your cable bender and compatible with the cable specifications you’re using.

Inspect Internal Components: Regularly inspect the internal components of the clamp, like springs and sliders, for signs of wear or damage. Replace or repair any faulty components to ensure proper functionality.

Check the Control System (if needed): While less frequent, control system malfunctions can occur. If you suspect this is the issue, it’s best to consult a qualified technician for a thorough inspection and potential repairs.

Safety First: Keeping You and Your Machine Safe

Working with machinery requires prioritizing safety at all times. Here are some safety reminders:

Protective Gear: Always wear appropriate personal protective equipment (PPE) when operating the cable bender. This may include gloves, safety glasses, and hearing protection, depending on your specific machine.

Follow Procedures: Strictly adhere to the operating procedures outlined in your machine’s user manual. This helps to avoid accidents and equipment damage due to improper operation.

Maintaining the Grip: Prevention is Key

Regular maintenance is essential for keeping your cable bender operating smoothly and efficiently. Here are some preventative measures:

Scheduled Maintenance: Perform periodic maintenance checks according to the manufacturer’s recommendations. These checks may involve cleaning the clamp components, lubricating moving parts, and inspecting for wear and tear.

Clamp Selection: When replacing the clamp, ensure you select the correct model compatible with your cable bender and cable specifications. Refer to the user manual for specific replacement guidelines.

By understanding the causes of faulty clamps and implementing the solutions provided, you can diagnose and fix clamping issues efficiently. Remember, prioritizing safety, following proper operating procedures, and conducting regular maintenance are key to keeping your cable bender gripping tight and your production running smoothly.

Find expert automatic wire cutter stripper technical resources on our specialized page.