Troubleshooting Automatic Rigid Plastic Tube Cutting Machine That Fails to Cut

I. Deformed Pipes Resulting in Incomplete Cuts

During the cutting process, pipes can easily become deformed, preventing a smooth cut. There are many reasons for pipe deformation, the most common being accidental damage from workers during transportation or storage, which alters the pipe’s shape. If this happens, you should immediately check for deformation and replace the pipe promptly. Additionally, when using the automatic rigid plastic tube cutting machine, pay attention to the pipe’s dimensions and hardness to avoid excessive pressure that could cause deformation.

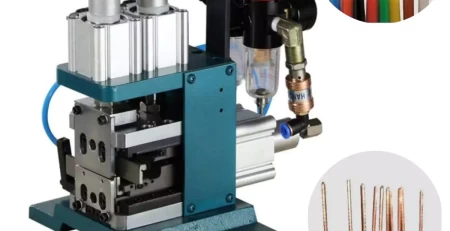

II. Damaged Cutting Blade

The cutter’s blade can easily wear out due to long-term use and friction, leading to a failure to cut properly. In this case, you need to replace the old blade and adjust its position and cutting pressure according to your specific requirements. The cutting edge should also be kept clean to maintain the blade’s sharpness and cutting efficiency.

III. Excessive Cutting Speed

If the cutting speed is set too high, the pipe may break mid-cut, forcing workers to spend time readjusting the cutting position and checking the results, which significantly lowers work efficiency. Therefore, when operating the cutting machine, you should reasonably control the cutting speed based on the material and shape of the pipe. You should also constantly monitor the cutting quality and position to ensure the pipe is cut successfully.

In summary, the problem of a pipe cutter failing to cut has various causes. Workers need to pay attention to details and perform daily maintenance, checking and replacing equipment in a timely manner to ensure the cutter’s efficiency and stability.