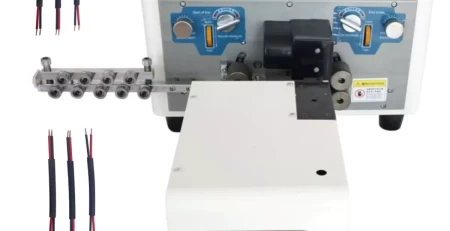

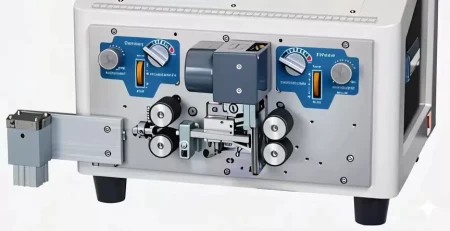

Crimp Like a Pro! Fix Multi-Core Cable Strip & Crimp Machine

The multi-core cable stripping and crimping machine is a precision tool designed for efficient wire termination. Proper operation and maintenance are essential to ensure consistent performance and avoid common issues such as loose terminals, production interruptions, and irregular crimps. This guide provides detailed troubleshooting methods and best practices for optimal machine performance.

I. Safety and Initial Setup Checks

Before operating the terminal machine, perform the following checks to avoid malfunctions:

1. Power and Electrical Connections

Ensure the power cord is securely plugged into both the power socket and the machine’s power input.

Verify that the wiring board connections are correct and firmly attached.

2. Machine Integrity Checks

Confirm that the protective door is fully closed to prevent operational hazards.

Inspect the circuit continuity between the plug and socket to rule out electrical faults.

3. Professional Assistance

If issues persist after these checks, consult a qualified technician to avoid further damage.

II. Troubleshooting Loose Terminals

Loose terminals can compromise electrical connections. Below are common causes and solutions:

1. Terminal Fastening Issues

Cause: Buttons may be flipped or loosened; screws may be over-tightened or too loose.

Solution:

Recheck if all machine buttons are tightly secured.

Ensure brass compression screws are symmetrically tightened.

Verify that U-shaped brass pieces have uniform thickness.

Adjust the screw to the optimal pressure setting.

2. Worn or Misaligned Terminal Teeth

Cause: Blunt teeth or incorrect cutter angles reduce grip.

Solution:

Replace with sharper terminal teeth or stripping heads.

Increase friction between teeth and terminal copper sheets for a tighter crimp.

III. Fixing Intermittent Terminal Production

If the machine fails to produce terminals continuously, follow these steps:

1. Mechanical Inspection

Check if fixing screws and eccentric components are tight and movable.

Ensure terminal copper strips are of equal length and free from impurities.

Restart the machine to reset any temporary malfunctions.

2. Terminal Teeth Condition

Inspect for fatigue or wear—replace if necessary.

IV. Resolving Irregular Terminal Crimps

Poor crimping quality can lead to weak connections. Follow these corrective measures:

1. Proper Wire Preparation

Ensure the copper wire is cut flat and stripped evenly.

The terminal outlet length should not exceed 1mm to maintain crimp tightness.

2. Adjusting Stripping Parameters

Reduce excessive wall thickness by modifying the stripping operation.

Optimize the crimping pressure for consistent terminal formation.

V. Best Practices for Terminal Machine Operation

1. Pre-Operation Checks

Confirm power supply stability and air pressure levels before starting.

Operate on a dedicated workbench to ensure stability.

2. Safety and Maintenance

Avoid wearing gloves to prevent entanglement in moving parts.

Regularly clear waste materials to prevent jamming.

3. Terminal Compatibility

For BHT1.25-BHT14 terminals, use the 23DW model.

Other terminal types require model-specific adjustments.

[Conclusion]

This article provides detailed answers to common problems encountered when using the Multi-Core Cable Stripping and Crimping Machine, including issues with machine usability, loose terminals, inability to produce continuous terminals, and irregular terminals. It also offers corresponding solutions and operating techniques. During the use of the terminal machine, it is important to adhere to relevant safety procedures to prevent accidents.

Find expert terminal crimping machine technical resources on our specialized page.