Wire Crimping Machine Issues: Analyzed

What factors contribute to sour connectivity in wire crimping machines?

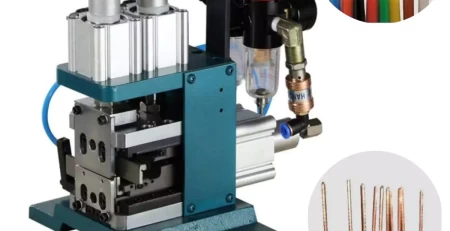

Relating the root causes of poor contact in wire crimping machines is essential, as it stands as a primary malefactor for malfunctions in colorful bias, from compact smartphones and computers to larger– scale outfit similar as wire crimping machines and aeronautics bias. Given the critical nature of this issue, it demands scrupulous attention. moment, let’s cave into the analysis of contact– related challenges in wire crimping machines, courtesy of perceptivity from the Fortune Sky Terminal Connector Manufacturer.

In the realm of computers, conking frequently finds its center in memory modules. still, for wire crimping machines, the crux of poor contact lies within the internal essence operators of the releasing outstations. These factors constitute the heart of the releasing system, easing the transmission of voltage, current, or signals from external cables or lines to the corresponding contact points on the connector.

Due to the consummate significance of these factors, wire crimping machines must meet strict criteria, encompassing stable and dependable contact along with estimable electrical conductivity. Now, let’s explore the myriad factors that can lead to compromised contact structures in wire crimping machines.

Introduction: Understanding Connector Reliability Challenges

Modern automated wire crimping machines face numerous reliability challenges stemming from connector system failures. This technical analysis examines the three primary failure modes affecting electrical connectors – contact issues, insulation defects, and fixation problems – while providing actionable solutions for manufacturing quality improvement.

Section 1: Contact Point Failures – The Weakest Link

Root Causes of Contact Degradation

Structural Design Flaws

Inadequate contact retention force design

Improper mating geometry

Insufficient normal force calculations

Material Selection Errors

Incorrect base metal choices (e.g., brass vs. phosphor bronze)

Suboptimal plating materials (gold vs. tin)

Incompatible spring characteristics

Manufacturing Process Deficiencies

Dimensional tolerances exceeding ±0.05mm

Surface roughness (Ra) > 0.8μm

Improper heat treatment parameters

Electroplating thickness inconsistencies

Performance Impacts

Increased contact resistance (>5mΩ)

Intermittent signal transmission

Voltage drop exceeding 3% of rated value

Current carrying capacity reduction up to 40%

Section 2: Insulation System Failures

Critical Insulation Requirements

| Parameter | Industrial Standard | Failure Threshold |

|---|---|---|

| Dielectric Strength | 1000V/mm | <500V/mm |

| Insulation Resistance | 10⁹Ω | <10⁶Ω |

| Comparative Tracking Index | 600V | <250V |

| Water Absorption | 0.1% | >0.5% |

Common Failure Mechanisms

Material Contamination

Metal flash from molding (>0.2mm particles)

Solder flux residues

Mold release agent accumulation

Environmental Degradation

Moisture absorption (>0.3% by weight)

Fungal growth in humid environments

Thermal aging at >105°C continuous

Processing Defects

Voids in insulation walls (>0.1mm diameter)

Incomplete mold filling

Weld lines in critical areas

Section 3: Fixation and Mechanical Stability Issues

Connector Retention Failure Modes

Primary Locking Mechanism Failures

Housing latch strength <50N

COP (Change of Point) in mating cycle >1000

Wear particle generation >5mg/1000 cycles

Secondary Locking Problems

CPA (Connector Position Assurance) failure

TPA (Terminal Position Assurance) displacement

Backout force <15N

Terminal Fixation Issues

Retention force variance >±20%

Primary lock bending stress >500MPa

Secondary lock engagement depth <0.5mm

Consequences of Fixation Failures

Intermittent connections during vibration

Complete circuit interruption

Arc damage at separating contacts

Overheating at high current applications

Section 4: Quality Control Solutions

Advanced Detection Methods

Automated Optical Inspection

5MP camera systems with 10μm resolution

Machine learning defect recognition

100% inline inspection capability

Process Monitoring

Real-time mold pressure tracking (±1Bar)

Plating thickness measurement (XRF)

Dimensional verification (laser micrometer)

Environmental Testing

85°C/85% RH damp heat testing

50G mechanical shock verification

Vibration testing 10-2000Hz

Section 5: Design Improvement Strategies

Contact System Enhancements

Finite element analysis for stress optimization

Cross-section design validation

Fretting corrosion simulation

Material Advancements

Liquid crystal polymer insulation

Nanocomposite dielectric materials

High-performance contact platings

Manufacturing Process Controls

Six Sigma process capability (CpK>1.67)

Automated process adjustment systems

Statistical process control charts

Conclusion: Building Reliability into Connector Systems

By addressing these failure modes through:

Robust design validation

Precision manufacturing controls

Comprehensive testing protocols

Manufacturers can achieve:

→ 99.9% connector reliability

→ <50ppm defect rates

→ 10-year service life guarantees

Implement these solutions today to eliminate connector failures in your wire crimping operations. [Contact our engineering team] for customized reliability improvement programs.

Find expert wire crimping machine technical resources on our specialized page.