Wire Cutter & Stripper Machines for New Energy

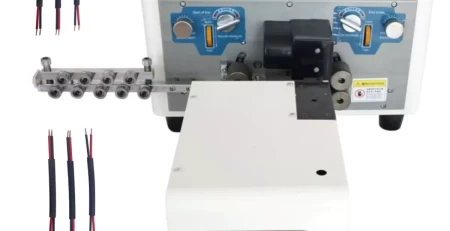

The global transition to renewable energy and electrification has created unprecedented demand for high-performance wire processing solutions. Whether manufacturing EV battery harnesses, solar panel interconnects, or wind turbine wiring systems, selecting the right wire cutter and stripping machine is essential for quality, efficiency, and long-term reliability.

This guide provides a comprehensive framework for evaluating machines, balancing performance, durability, and value, while addressing the unique challenges of new energy applications.

1. Quality Assessment: Ensuring Reliability in Demanding Environments

1.1 Pre-Purchase Testing (Ideal Scenario)

Conduct real-world trials using your specific wire types (e.g., high-voltage silicone cables, fine-stranded copper).

Verify:

✅ Stripping accuracy (±0.05mm tolerance for critical connections)

✅ Cut consistency (burr-free, no conductor deformation)

✅ Speed vs. precision trade-offs (e.g., 500+ cuts/hour without quality loss)

Note: If testing isn’t feasible, prioritize ISO 9001-certified manufacturers with documented performance data.

1.2 Physical Inspection Checklist

✔ Robust Construction – Look for anodized aluminum frames and stainless steel blades resistant to:

Battery acids

UV exposure (for solar applications)

Salt spray (marine/wind energy use)

✔ Smooth Operation – The stripping mechanism should:

Adjust seamlessly for insulation thickness variations

Avoid wire nicking or strand breakage

2. Cost vs. Value: Avoiding Pitfalls in Procurement

2.1 The “Too Cheap” Trap

Low-cost machines often compromise on:

Blade longevity (requiring frequent replacements)

Motor durability (overheating in high-duty cycles)

Electronics reliability (poorly calibrated sensors)

Example: A 3,000machinemaysaveupfrontcostsbutrequire1,500/year in maintenance vs. a $6,000 machine with 5+ years of service.

2.2 Overpriced Mediocrity

Red flags of inflated pricing:

Lack of third-party certifications (UL, CE)

Vague technical specifications (e.g., “high speed” without RPM data)

No customer performance testimonials

Solution: Cross-reference pricing with industry benchmarks (e.g., machines with similar specs from Schneider Electric, Komax, or Artos).

3. Manufacturer Selection: Partnering for Long-Term Success

3.1 Due Diligence Steps

Facility Tour – Assess:

Automation level (robotic assembly vs. manual labor)

QC processes (e.g., 100% electrical testing)

Ask for:

Material certifications (e.g., RoHS-compliant components)

Warranty claims history (low return rates = reliable design)

3.2 New Energy-Specialized Manufacturers

| Manufacturer | Specialization | Notable Feature |

|---|---|---|

| Schleuniger | EV battery wiring | Laser-guided stripping |

| Metzner | Solar cable processing | UV-resistant tooling |

| Carpenter Mfg. | High-voltage harnesses | 20mm² capacity |

4. Technical Considerations for New Energy Applications

4.1 Key Machine Specifications

Parameter EV Requirement Solar/Wind Requirement

Wire Gauge 0.5–16mm² 2.5–35mm²

Stripping Length 0.5–15mm (precision) 5–50mm (heavy-duty)

Speed 300–600 cuts/hour 200–400 cuts/hour

Insulation Types Teflon, silicone XLPE, EPR

4.2 Advanced Features Worth Investing In

Automated Vision Inspection – Detects micro-cuts in strands (critical for high-current paths).

Adjustable Torque Control – Prevents conductor deformation in fine wires.

IoT Connectivity – Enables predictive maintenance (e.g., blade wear alerts).

5. After-Sales Support: Minimizing Downtime

5.1 Non-Negotiable Service Elements

✔ 24/7 Technical Hotline – For urgent production line issues.

✔ On-Site Training – Ensures operators avoid common setup errors.

✔ Spare Parts Inventory – Verify 3-day delivery for critical components.

5.2 Warranty Comparison

Standard: 1 year (limited coverage)

Premium: 3 years (includes wear parts like blades)

Pro Tip: Negotiate extended warranty packages for high-uptime operations.

Conclusion: Future-Proofing Your Wire Processing

For new energy applications, the “right” machine is one that:

✅ Meets today’s precision demands (e.g., 0.1mm stripping accuracy)

✅ Adapts to tomorrow’s materials (e.g., solid-state battery cables)

✅ Integrates with smart factories (Industry 4.0 readiness)

Actionable Next Steps:

Shortlist 3–5 models matching your wire specs.

Request live demos (onsite or virtual).

Audit supplier service networks before committing.

The energy transition starts with flawless connections—choose wisely.

By prioritizing quality, carefully evaluating price and value, selecting a reputable manufacturer, and considering these additional factors, you can choose the ideal wire cutter and stripping machine to optimize your new energy wire processing needs.