Protect Wires in Harsh Conditions: Wire Loom Tubing

Wire Loom Tubing: A Reliable Performer in Demanding Applications

Selecting the appropriate conduit material is crucial in modern engineering and industrial settings. Nylon’s versatility transcends its widespread use in everyday applications, showcasing its remarkable potential in diverse fields. Wire loom tubing, specifically, emerges as a champion in specialized fields like electrical engineering and the chemical industry, offering superior flame resistance, high-temperature tolerance, and exceptional protection against corrosion.

Understanding Wire Loom Tubing

Wire loom tubing, also known as nylon corrugated tubing, is a flexible conduit constructed from polyamide (nylon) material. Its defining characteristic is the corrugated or wavy exterior surface. This unique design structure enhances its wear resistance, corrosion resistance, flame retardancy, and flexibility. These qualities make it well-suited for navigating complex environments and tackling specialized applications.

Key Strengths of Wire Loom Tubing

Flame Retardancy: Wire loom tubing boasts impressive fire resistance, acting as a flame retardant and offering valuable time for implementing safety protocols during fire emergencies.

High-Temperature Tolerance: It maintains stability at elevated temperatures, typically within the range of -40°C to +120°C, allowing it to excel in applications demanding high-temperature resilience.

Corrosion Resistance: Wire loom tubing demonstrates exceptional resistance to common chemicals and corrosive media, making it a valuable asset in the chemical industry for applications like chemical transfer.

Enhanced Mechanical Strength: The base material, nylon, possesses inherent mechanical strength. The corrugated design further bolsters its resistance to compression and tensile forces.

Electrical Insulation: Wire loom tubing serves as a prime electrical insulator. It is extensively used in electrical engineering, effectively safeguarding cables by preventing electrical current leakage and ensuring optimal protection.

Lightweight Advantage: Compared to metal conduits, wire loom tubing boasts a significantly lighter weight. This translates to reduced costs associated with installation and transportation.

Diverse Applications

Wire loom tubing’s versatility extends across a broad spectrum of industries, including:

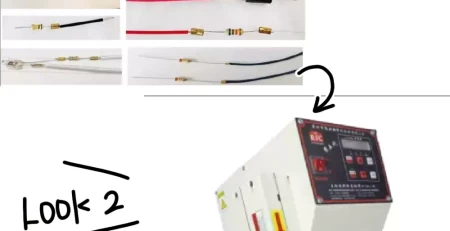

Electrical Engineering: Used as cable protection conduits, it delivers both electrical insulation and superior wear resistance, safeguarding valuable electrical cables.

Chemical Industry: It finds application in transporting corrosive chemicals and fluids at elevated temperatures, ensuring safe and reliable transfer.

Automotive Engineering: In automobile manufacturing, it acts as a protective sleeve, shielding sensor wiring and other conduits from damage.

Mechanical Manufacturing: Offering reliable protection, it safeguards mechanical equipment, essential conduits, and hydraulic transmission systems.

A Champion for Challenging Environments

Wire loom tubing, with its exceptional combination of flame retardancy, high-temperature tolerance, and impressive corrosion resistance, stands out as a reliable performer in numerous engineering and industrial applications. Its remarkable performance characteristics position it as the preferred choice for complex environments and specialized requirements. Whether in electrical engineering, the chemical industry, or automotive manufacturing, wire loom tubing delivers an exceptional solution for ensuring safe and reliable fluid transport and cable protection.