Hidden Dangers of Wire Terminal Crimping?

Wire Terminal Crimping Machine Safe Operation Guidelines

Safe Operating Procedures

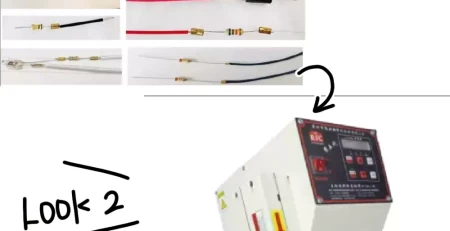

Start by turning on the power switch to confirm if the power is on. When the power is on, the indicator light on the switch will illuminate. Pay attention to any noticeable abnormal sounds inside or outside the machine. If any issues are observed, pause the operation and have the machine repair personnel assess whether maintenance is required. For installing blades, it should be handled by technical personnel. Before installing the blade, manual verification of the selected blade’s compatibility is mandatory. After confirming the compatibility, proceed with the installation. After installing the blade, perform a manual test using the hand crank. First, turn off the power to the wire terminal crimping machine, press the adjustment knob, and use a special wrench to manually rotate the master and slave wheels, driving the crimping stroke to the maximum. If the hand crank is immovable, consider whether the pressure is too high or there are other issues. Check and adjust until the crimping stroke reaches the maximum without damaging the terminals, and the terminal pull-off force meets the standards.

Before starting the operation, check and confirm that all locking screws are securely tightened.

Loading: Install the terminals that need to be crimped. Use an Allen wrench to adjust the feed pressure plate so that the terminals can pass through easily. Visually inspect whether the feeding position is appropriate. If not, make adjustments. Use an Allen wrench to loosen the feeder locking screw, turn the adjustment lever to make adjustments until the optimal state is reached, then tighten the feeder locking screw and start the operation.

Pull Force Testing: After the machine is adjusted, use scrap wire to test crimping and perform a pull force test. Refer to the “Pull Force Test Comparison Table” for the main reference values, and follow the “Pull Force Gauge Operation Guide” for specific testing procedures. If the measured pull force is not within the standard range, have the machine repair personnel readjust until the standard value is reached.

Conduct a trial production and send the products to IPQC for initial confirmation. Only after passing the inspection can mass production be carried out. Operators must conduct self-inspections during the production process to identify issues like encapsulation or hanging necks in crimped terminals. Additionally, perform a terminal pull force test every 2 hours.

Our company uses exquisite domestic craftsmanship and high-quality materials in the manufacturing of our products. To ensure product quality and performance, we conduct comprehensive inspections throughout the entire manufacturing process. Only after confirming compliance are the products boxed and stored. Before leaving the factory, products undergo quality testing and are professionally calibrated by technical personnel before being packed and shipped. We also provide product technical documentation and standard accessories and tools.

Find expert wire crimping machine technical resources on our specialized page.