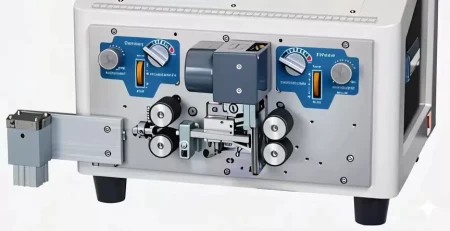

Setup and Adjustment Methods for Automatic Wire Cutter Stripper

Setup and Adjustment Methods for Automatic Wire Cutter Stripper

I. Adjustment of Stripping Blade Position

The stripping blade position significantly impacts stripping quality. Improper depth (too deep or shallow) may cause poor stripping. Follow these steps:

Locate the blade position by visual inspection (using light) or tactile confirmation.

Adjust the blade to contact the insulation without cutting into the conductor.

Test the result: Ensure complete insulation removal without conductor damage.

II. Cutting Depth Adjustment

Precise depth settings ensure optimal stripping:

Measure the conductor diameter to determine suitable depth.

Set the depth to remove all insulation while preserving the conductor.

Verify the result: Insulation should be fully cut but not nicking the conductor.

III. Stripping Force Adjustment

Force must match wire specifications:

Identify wire diameter and insulation material (e.g., PVC, Teflon).

Adjust the force based on insulation hardness and wire size.

Test the result: Stripped width should be consistent without conductor deformation.

IV. Stripping Speed Adjustment

Speed depends on wire type and material:

Select speed according to insulation properties (e.g., thicker insulation = slower speed).

Set the motor RPM to balance efficiency and precision.

Test the result: No residual insulation or conductor damage.

Safety & Maintenance

Wear gloves to prevent hand injuries.

Regular maintenance:

Clean blades and scrap collectors.

Lubricate moving parts.

Troubleshoot poor stripping by rechecking:

Blade position

Cutting depth

Force and speed settings

FAQ

Q: Why is stripping incomplete/uneven?

A: Possible causes:

Incorrect blade position

Insufficient cutting depth/force

Inconsistent speed

Q: Why is the conductor damaged?

A: Likely due to:

Excessive cutting depth

Excessive stripping force

Q: Why is speed inconsistent?

A: Potential issues:

Poor machine maintenance

Misaligned stripping blade

Find expert automatic wire cutter stripper technical resources on our specialized page.