Knowledge Guide: Advantages and Maintenance of Silent Wire Splicing Machines

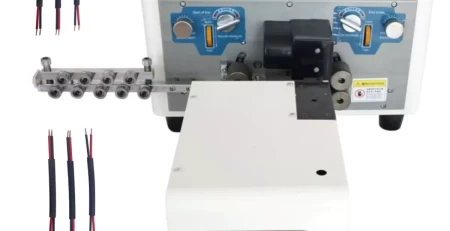

First, let’s understand the principle of the silent wire splicing machine. The silent wire splicing machine is an automated processing device for crimping copper tapes to wires that require riveting. It is a machine that cuts, forms, and crimps continuous copper tape terminal materials in one step, providing a convenient way to connect wires. It replaces traditional soldering, is safe and pollution-free, produces no waste, and saves costs.

In addition to using high-tech variable frequency technology and precise electronic positioning—where the motor only works during crimping, resulting in less noise and power consumption than traditional models—it also offers more convenient and faster mold adjustments, avoiding common faults like the clutch and electromagnet found in traditional machines. It also has five other advantages:

I. Specifically designed for wires requiring riveting, offering high speed and good quality.

II. Crimp-connecting wires replaces traditional soldering, eliminating the disadvantages of cold soldering, open soldering, and air pollution. It is the simplest and most effective way to pass various safety standards tests (UL/JIS).

III. The special continuous copper tape terminal material (patent pending, do not counterfeit) is cut, formed, and crimped in one step. This is fast and produces no waste, saving costs.

IV. The copper tape terminals are treated with a special texture, resulting in exceptionally strong tensile resistance and stable quality after riveting.

V. Equipped with a bending die base for connecting different products. The user-friendly design allows for operation without extensive training.

Finally, let’s look at the practical applications of the silent wire splicing machine, which can be divided into five categories:

I. Connection of neon lights and resistors, and the connection of LEDs and wires.

II. Connection of slide switches and wires (replaces hook soldering).

III. Connection of high-temperature heating elements.

IV. Connection of sensitive components (such as reed switches and thermal fuses).

V. Connection of transformer taps and wires.

The silent wire splicing machine is widely used in electronics and appliance factories, and its regular maintenance is crucial. Do not run the machine continuously just to meet production deadlines. Both people and machines have a certain load capacity. During use, employees should know how to maintain the equipment to ensure it operates normally and has a longer service life.

Pay attention to the following points for maintenance:

1. The wire splicing machine mold must be clamped accurately and securely. The mold clearance should be reasonable, and the blade edges should be kept sharp.

2. Do not overload the wire splicing machine. The stamping pressure of the processed workpiece must not exceed the specified range.

3. Before starting the wire splicing machine motor, the clutch must be in the disengaged state and the flywheel in the idling position.

4. The stamping guide rail must be lubricated with machine oil once every hour. The oil hole is on top of the crimping machine. 2-3 drops of oil are sufficient each time; do not add too much. Employees must clean the machine daily, removing dust, debris, and excess oil from its surface.

5. Regularly check whether all parts of the wire splicing machine are working properly and if all connections and fasteners are loose. If any are loose, tighten them in time. If any parts are found to be worn, they must be replaced immediately.

6. After changing the copper tape, use the manual function to crimp and form a sample. If it works correctly, you can proceed with batch operation.