How to Set Parameters for Automatic Wire Cutting Stripping Terminal Crimping Machines

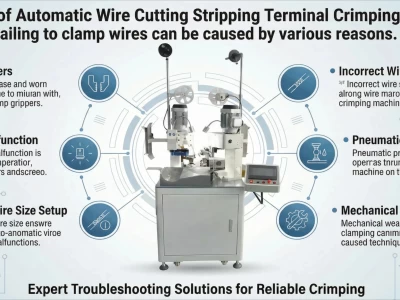

Debugging Methods for Automatic Wire Cutting Stripping Terminal Crimping Machines I. How to Set Parameters for Automatic Wire Cutting Stripping Terminal Crimping Machines As an automated equipment used in the production of electrical connectors, the proper parameter settings of the Automatic Wire Cutting Stripping Terminal Crimping Machine are crucial for enhancing production efficiency and product quality. First, adjusting the pressure parameters is key. Depending on the material and specifications of the workpiece, the pressure should be appropriately increased or decreased to ensure the...