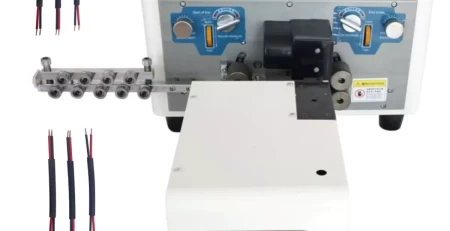

Fix Wire Processing! Auto Cut/Strip/Solder Machine

Automatic Wire Cutting, Stripping, and Dip Soldering Machine: Troubleshooting Common Issues

Modern manufacturing demands for wire processing are becoming increasingly intricate. Automatic wire cutting, stripping, and dip soldering machines (often abbreviated as AWCSS machines) play a vital role, ensuring neatly cut and stripped wires with a uniform, smooth solder coating. However, achieving consistent results requires attention to detail and proper machine operation. Let’s explore potential issues that may arise during full and point soldering processes, along with solutions to ensure optimal performance.

Full Dipping Challenges:

Incomplete Tinning: This manifests as a slight residue of exposed wire near the insulation after soldering.

Burned or Contracted Insulation: While the wire may be fully tinned, the insulation appears discolored or shrunk.

Microscopic Inspection Reveals Inconsistencies: Closer examination under a microscope might reveal uneven solder application, gaps, pointed tips, or large solder heads.

Point Dipping Challenges:

Tinning Length Deviation: The actual tinned length may differ from the desired specification.

Microscopic Inspection Reveals Imperfections: Similar to full dipping, microscopic inspection might reveal uneven solder application, gaps, pointed tips, or large solder heads after soldering to the designated length.

Addressing these issues requires a well-designed AWCSS machine with readily adjustable components. High-quality raw materials, including solder bars, solder wires, and flux, are equally important. The viscosity of the high-temperature solder compared to regular solder, as well as the strength of the flux, significantly impact the outcome.

Here’s a breakdown of key features that contribute to consistent soldering:

Precise Temperature Control: A stepper motor accurately controls a 90-degree fixture rotation for horizontal contact with the environmentally friendly titanium tin furnace surface. A temperature controller and a 200W heating tube ensure stable furnace temperature, crucial for optimal solder flow and quality.

Adjustable Tin Furnace Height and Rotation: The ability to conveniently adjust the tin furnace height and achieve precise 90-degree rotation positioning allows for optimal contact between the wire and the solder surface.

Automatic Solder Feeding and Flux Adjustment: Automatic solder feeding maintains a consistent horizontal solder surface, while flux application can be adjusted based on wire size through a screen adjustment mechanism.

By implementing these features, AWCSS machines can effectively prevent the issues mentioned earlier.

Solutions for Specific Challenges:

Full Dipping:

Flux Selection: For full dipping, a flux with strong viscosity is recommended. When roughly 2/3 of the wire core enters the flux holder, a 90-degree rotation into the tin furnace ensures the solder surface is approximately 1mm away from the insulation. This prevents burning and incomplete tinning.

Temperature and Time Adjustments: If the tinning appears uneven or has gaps, slight adjustments to the tin furnace temperature and tinning time can usually resolve the issue.

Wire Twisting: Tin tips or large heads are generally caused by inadequate wire twisting. Properly twisting the wires before dipping can eliminate this problem.

Point Dipping:

Flux Selection: For point dipping, a flux with lower viscosity is preferable. The amount of solder applied will correspond to the amount of flux adhering to the wire core.

Temperature Control: The tin furnace temperature needs to be suitable to prevent excessive upward tin flow during point dipping.

Temperature and Time Adjustments: Similar to full dipping, adjustments to the tin furnace temperature and tinning time can address uneven tinning and gaps.

Wire Twisting: As with full dipping, proper wire twisting is essential to avoid tin tips or large heads.

In conclusion, this article has explored common challenges encountered during wire soldering with AWCSS machines and provided solutions to achieve consistent, high-quality results. By understanding these factors and utilizing a well-designed machine, manufacturers can ensure their wire processing meets the ever-increasing demands of modern production.