Automatic Terminal Crimping Machine Won’t Clamp? Diagnose & Fix It Fast

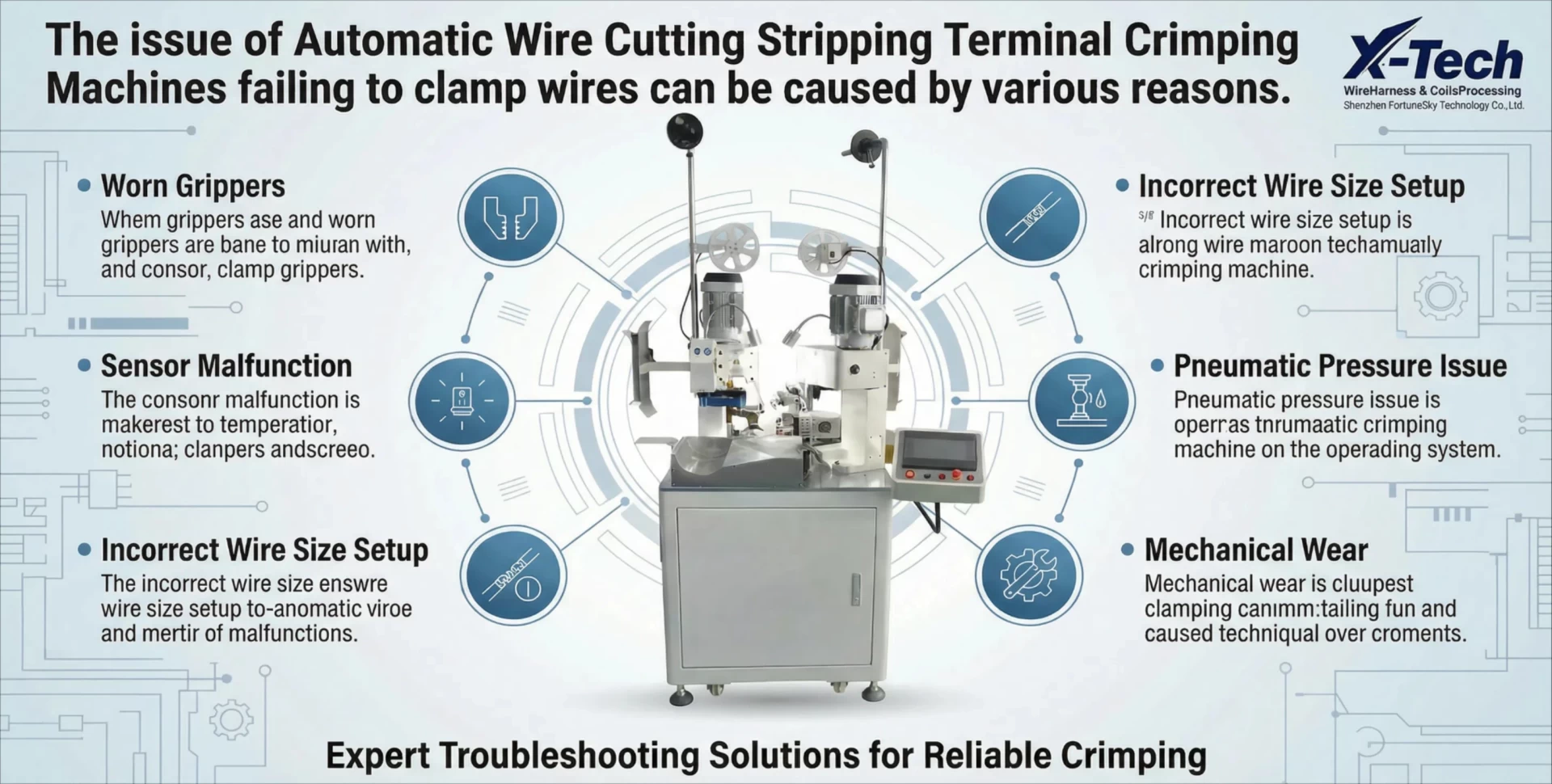

The issue of Automatic Wire Cutting Stripping Terminal Crimping Machines failing to clamp wires can be caused by various reasons. Below are common causes and solutions:

Malfunction of the Wire Clamping Mechanism

The clamping mechanism may wear out or become loose due to prolonged use, resulting in ineffective wire clamping. Check the springs and clamping jaws of the mechanism for damage or looseness, and replace or adjust them if necessary.

Mismatched Wire Specifications

If the diameter or material of the wire does not match the clamping mechanism of the machine, clamping failure may occur. Ensure the wire meets the design requirements of the machine, and adjust the clamping pressure or replace the jaws as needed.

Insufficient Air Pressure

Some Automatic Wire Cutting Stripping Terminal Crimping Machines rely on air pressure to drive the clamping mechanism. Check whether the air pressure is stable and ensure it is within the required range (typically 0.4–0.6 MPa).

Incorrect Program Settings

The program parameters of the machine (such as clamping time and pressure) may be improperly set. Recalibrate the program to ensure the clamping time and pressure align with the wire’s characteristics.

Foreign Object Blockage

The clamping mechanism may be clogged with wire debris or other foreign objects, preventing normal clamping. Regularly clean the clamping mechanism to keep it clear.

Sensor Malfunction

The sensors in the clamping mechanism may be damaged or malfunctioning, failing to detect the wire. Check whether the sensors are working properly and replace them if necessary.

Wire Surface Issues

Oil stains, oxidation layers, or coatings on the wire surface may prevent the clamping mechanism from gripping effectively. Clean the wire surface or replace it with wires that meet the requirements.

Equipment Aging

Long-term use of the machine may lead to overall performance degradation. Regular maintenance or replacement of key components is recommended.

Solutions:

First, check whether the clamping mechanism is functioning properly. Clean any foreign objects and adjust the jaw pressure.

Confirm that the wire specifications match the equipment. Replace the wire or jaws if necessary.

Check the air pressure and program settings to ensure the parameters are correct.

If the problem persists, contact the equipment manufacturer or professional technicians for inspection and repair.

Preventive Measures:

Regularly maintain the machine, clean the clamping mechanism, and lubricate moving parts.

Use wires that meet the required specifications and avoid substandard or incompatible materials.

Periodically calibrate the machine’s program to ensure accurate parameters.