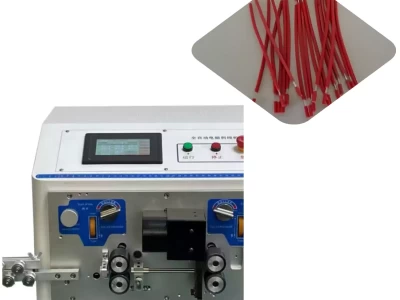

Optimize harness machine performance: faster, safer operation & extended lifespan.

Wire Terminating Machine Classification

Wire terminating machines can be categorized into several distinct groups, included Automatic Wire Cut Strip Terminating Machines, Multi-conductor Cable Stripping and Crimping Machine, ultra-silent wire terminating machines, pneumatic wire crimping machines, terminal crimping machines, computerized wire stripping and crimping machines, pin insertion wire crimping machines, and gold wire crimping machines. I. Categorizing Fully Automatic Wire Crimping Machines: A Breakdown: Fully automatic single-head wire crimping machine (controlled by PLC or microcontroller). This domestically manufactured equipment boasts an impressive output of 5,000 wire cutting,...