Optimize harness machine performance: faster, safer operation & extended lifespan.

Perfect Jacket/Insulation Strips: Safe & Efficient Guide

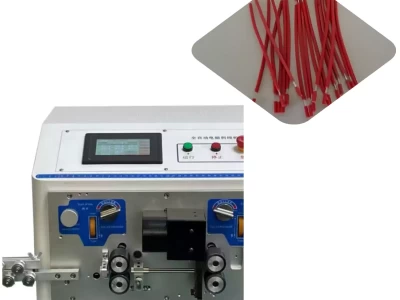

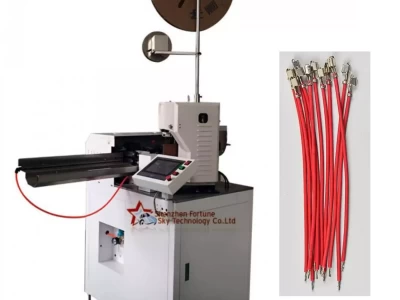

Perfect Jacket/Insulation Strips: Safe & Efficient Guide This guide empowers you to harness the full potential of your automatic cable jacket insulation stripping machine (referred to here as the "stripping machine"). By understanding its capabilities and following these guidelines, you can achieve efficient and safe wire processing. Prioritizing Safety Safety always comes first. The user manual is your essential companion. Read and comprehend all safety instructions before operating the machine. Here's a quick safety checklist: Ground Control: Ensure proper grounding before powering up the...