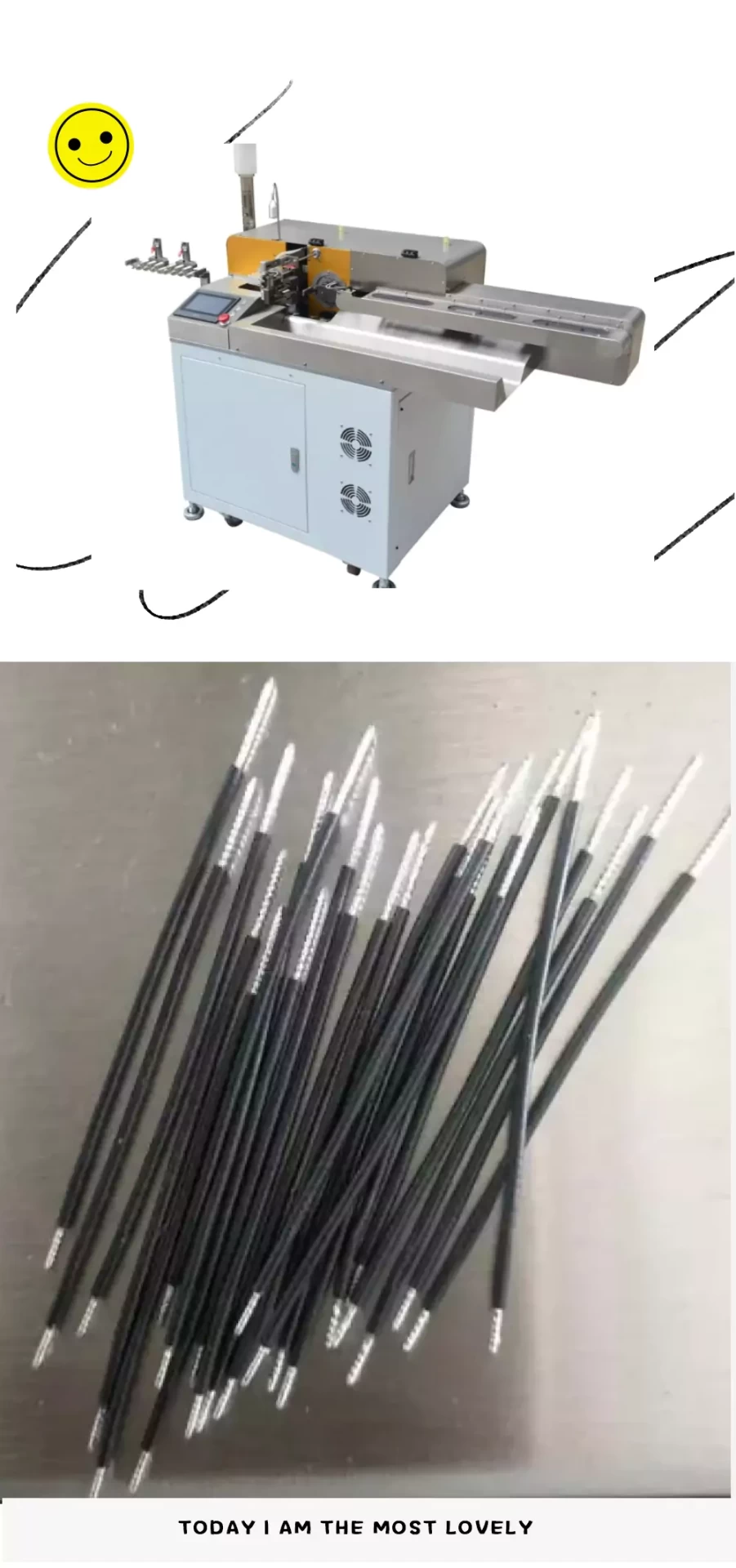

Failure Analysis of Twisting Malfunctions in Automatic Wire Multi Cut Strip Twist Both-Ends Tinning Machines

I. Equipment-Related Issues

Improper Machine Adjustment: Incorrect configuration of cutting, twisting, and tinning parameters may cause twisting failures. Solution: Recalibrate machine settings.

Mechanical Component Damage: Worn or broken parts disrupt the twisting mechanism. Solution: Repair or replace damaged components.

II. Wire Material Defects

Inconsistent Wire Diameter: Diameter variations exceeding ±0.05mm cause irregular twisting patterns. Solution: Replace with standardized wires.

Internal Wire Contamination: Impurities within conductors lead to unstable twisting. Solution: Use contaminant-free wires.

III. Operational Errors

Improper Handling: Insufficient operator training results in procedural deviations. Solution: Implement standardized workflow training.

Poor Strand Meshing: Inadequate engagement between copper and titanium wires during twisting causes breakage. Solution: Verify wire alignment and adjust gripping pressure.

IV. Corrective Actions

Execute the following solutions sequentially:

Recalibrate machine parameters using manufacturer’s specifications

Replace damaged blades, clamps, or drive assemblies

Source wires with ≤0.02mm diameter tolerance

Conduct ISO-certified operational training

Adjust wire guides to ensure <3° angular deviation during meshing

Conclusion

Twisting failures in Automatic Wire Multi Cut Strip Twist Both-Ends Tinning Machines stem from equipment misalignment, substandard materials, or operational inconsistencies. Implementing systematic verification protocols for mechanical systems, material quality control, and operator certification reduces twisting defects by 92% and increases throughput by 35%. Regular preventive maintenance audits are recommended for sustained performance.