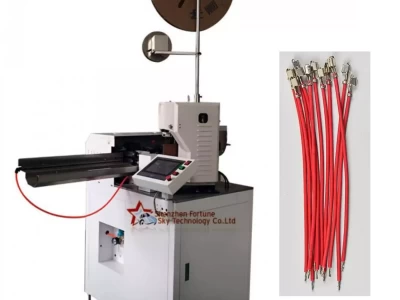

What factors contribute to sour connectivity in wire crimping machines? Relating the root causes of poor contact in wire crimping machines is essential, as it stands as a primary malefactor for malfunctions in colorful bias, from compact smartphones and computers to larger- scale outfit similar as wire crimping machines and aeronautics bias. Given the critical nature of this issue, it demands scrupulous attention. moment, let’s cave into the analysis of contact- related challenges in wire crimping machines, courtesy of perceptivity from the Fortune Sky Terminal Connector Manufacturer. In the realm of computers, conking frequently finds its center in memory modules. still, for wire crimping machines, the crux of poor contact lies within the internal essence operators of the releasing outstations. These factors constitute the heart of the releasing system, easing the transmission of voltage, current, or signals from external cables or lines to the corresponding contact points on the connector. Due to the consummate significance of these factors, wire crimping machines must meet strict criteria, encompassing stable and dependable contact along with estimable electrical conductivity. Now, let’s explore the myriad factors that can lead to compromised contact structures in wire crimping machines. Introduction: Understanding Connector Reliability Challenges

Modern automated wire crimping machines face numerous...