Terminal Crimping Safety: Training & Tips

Safety First: Essential Safeguards for Chain Terminal Crimping Machine Operations

In any production environment, safety reigns supreme. Given the potential hazards associated with chain terminal crimping machines, proper precautions are critical. Here are some key steps to ensure safe operation:

Training and Supervision:

New Operator Training: New employees must always operate the chain terminal crimping machine under the direct guidance of experienced personnel. Unsupervised operation by untrained individuals is strictly prohibited.

Comprehensive Training: Prior to operating the machine for the first time, all operators must thoroughly review the user manual and become proficient in the main operating procedures. This ensures a clear understanding of the machine’s functionality and potential hazards.

Tool Installation and Inspection:

Dedicated Technicians: Tool installation should only be performed by designated and qualified personnel familiar with the specific machine.

Verification and Matching: Prior to installation, a manual check should be conducted to ensure the selected die matches the machine’s specifications. Only compatible tools should be used.

Manual Testing: Whenever possible, a manual lever test should be conducted after successful tool installation. With the power off, press the descent button and use a dedicated wrench to adjust the flywheel (master-slave relationship) to verify proper stroke alignment for punching and processing. If the lever is stiff or immovable, investigate the cause, such as high working pressure, and make adjustments before proceeding.

Locking Screw Inspection: Before starting operation, confirm that all locking screws are securely tightened to prevent tool movement during operation.

Safe Disassembly:

Power Down First: Always disconnect the power supply before attempting to disassemble terminals using the chain terminal crimping machine. Disassembly while the equipment is powered on is strictly forbidden.

Cleaning and Maintenance:

Post-Production Cleanup: Upon completion of production, properly dispose of high-quality and waste products. Clean the area surrounding the machine equipment to ensure a clear and safe work environment for subsequent use. Residual materials can pose potential hazards and should be removed.

Conclusion:

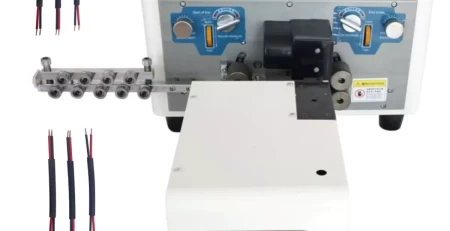

The chain terminal crimping machine plays a vital role in the wire processing industry, particularly within the power sector. These machines are used to attach hardware heads to wire ends and facilitate easy connection and disconnection of circuits. While these machines offer significant benefits in terms of efficiency and convenience, prioritizing safety is paramount. Implementing the precautions outlined above allows for safe and effective operation of chain terminal crimping machines, minimizing the risk of accidents and ensuring a smooth and productive work environment.