Explore PVC Wire Cutting Stripping Machine Precise Efficient

Unveiling Efficiency: Exploring the Functionality of the PVC Wire Cutting and Stripping Machine

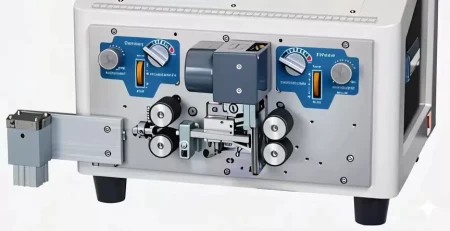

The PVC Wire Cutting and Stripping Machine offers an automated solution for precise wire processing. This innovative machine streamlines repetitive tasks, improving efficiency and consistency in wire cutting and stripping applications. Let’s delve into the machine’s core components and understand how they work together to achieve seamless wire handling.

The Art of Automation:

At the heart of the machine lies a system of interconnected components that work in unison to manipulate and process wires. The process follows a simple yet effective principle. The wire is first fed through the Inlet Wire Wheel, guided by its rotation. The Knife Rest Assembly then performs the cutting and stripping functions with precise control. Finally, the Outlet Wire Wheel guides the stripped wire out of the machine.

A Closer Look at Key Components:

Inlet Wire Wheel Uplift Knob: This knob adjusts the height of the Inlet Wire Wheel, allowing for easy loading and unloading of wires of various thicknesses.

Knife Rest Assembly: This crucial component houses the cutting blades and stripping tools. It ensures accurate and clean wire cutting and stripping.

Inlet Wire Wheel Gap Rotation Knob: This knob controls the distance between the Inlet Wire Wheel rollers. Adjusting this gap allows the machine to accommodate different wire diameters.

Inlet Wire Wheel: This continuously rotating wheel feeds the wire into the machine. For shorter wires, the Inlet Wire Wheel performs a partial strip before the wire reaches the Knife Rest Assembly for a full strip.

Outlet Wire Wheel Gap Rotation Knob: Similar to the Inlet Wire Wheel, this knob adjusts the spacing between the rollers of the Outlet Wire Wheel, ensuring the stripped wire exits smoothly.

Outlet Wire Wheel: This final wheel guides the stripped wire out of the machine. For short wires, the Outlet Wire Wheel rotates into a “U” position to facilitate easy retrieval.

Outlet Wire Wheel Lift-up Knob: This knob raises the Outlet Wire Wheel, allowing for convenient removal of the processed wire.

Outlet Wire Wheel Pressure Adjust Knob: This knob allows for fine-tuning the pressure applied by the Outlet Wire Wheel. This ensures optimal processing for wires of varying stiffness.

By understanding the functions of these individual components, users can effectively operate the PVC Wire Cutting and Stripping Machine for various wire processing tasks.

Conclusion:

The PVC Wire Cutting and Stripping Machine exemplifies the power of automation in streamlining wire handling processes. With its user-friendly design and intuitive controls, this machine offers a reliable and efficient solution for both experienced users and those new to automated wire processing.

Find expert wire stripping machine technical resources on our specialized page.