Multi Wire Twist Tin Machine Not Heating? Easy Fixes!

Multi Wire Twist Tin Machine Not Heating? Easy Fixes!

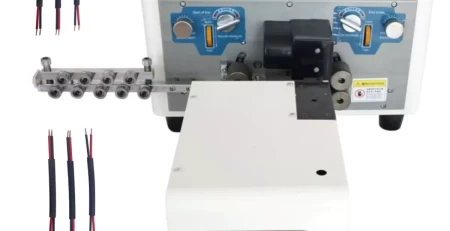

The Automatic Multi Twist drum( AMTT) 10- line Cutting Stripping Machine is a idler, streamlining line processing with its effective combination of slice, stripping, and tinning. But indeed the most reliable outfit can witness occasional interruptions, like a unlooked- for dip in solder pot temperature. This companion delves into common causes behind these temperature drops and offers results to get your machine back to peak performance.

The Preheating mystification A Matter of Time

Think of the AMTT’s solder pot like a machine machine. It needs a designated preheating time to reach its ideal operating temperature. Trying to rush the process by introducing lines before the pot is completely toast can lead to a struggle to maintain heat, eventually causing a temperature drop.

The Solution Always consult your machine’s primer for the recommended preheating time. Those spare beats allowing the pot to reach its optimal temperature can help product detainments and insure harmonious, high- quality results.

The Dirty Pot Problem Buildup and Heat Transfer

Over time, flux and other soldering remainders can accumulate inside the solder pot. analogous to how a dirty visage on the range conducts heat inadequately, this buildup can hamper effective heat transfer. This translates to temperature oscillations and a drop in the overall pot temperature.

The Solution Regular cleaning is essential for maintaining optimal performance. Follow the manufacturer’s recommended cleaning schedule to insure your solder pot remains free of pollutants and transfers toast effectively.

The Temperature Tango Control System Blues

In some cases, the malefactor behind the temperature drop might be the temperature control system itself. This could be due to incorrect settings or a implicit malfunction within the system.

The Solution Start by double- checking the temperature settings on your machine and insure they align with the manufacturer’s recommendations in the user primer. still, it’s voguish to communicate a good technician for prompt opinion and form, If you suspect a malfunction.

perquisite Tip preventative conservation for a Happy Machine

administering a regular conservation schedule is vital to precluding problems before they arise. By clinging to the manufacturer’s recommended conservation plan, which may include greasing moving corridor and vindicating electrical connections, you can insure your AMTT machine operates easily and efficiently for a long time.

By understanding these implicit causes and administering the handed results, you can effectively diagnose and address temperature drops within your AMTT Machine. Flash back, harmonious care and attention will keep your outfit performing optimally, guaranteeing harmonious and impeccable line processing for times to come.

The Solution Start by double- checking the temperature settings on your machine and ensure they align with the manufacturer’s recommendations in the stoner manual. However, it’s swish to communicate a good technician for prompt opinion and form, If you suspect a malfunction.

perquisite Tip precautionary conservation for a Happy Machine

administering a regular conservation schedule is pivotal to preventing problems before they arise. By adhering to the manufacturer’s recommended conservation plan, which may include greasing moving corridor and vindicating electrical connections, you can ensure your AMTT machine operates fluently and efficiently for a long time.

By understanding these implicit causes and administering the handed results, you can effectively diagnose and address temperature drops within your AMTT Machine. Flash back, harmonious care and attention will keep your outfit performing optimally, guaranteeing harmonious and impeccable line processing for times to come.