Troubleshoot wire crimping machines effectively for optimal performance and production efficiency.

Need Top-Tier Crimping? Automatic Machines Compared

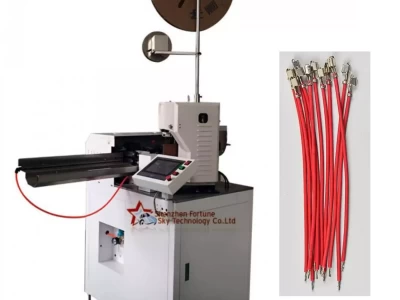

Need Top-Tier Crimping? Automatic Machines Compared Selecting high-quality equipment not only helps a company gain profits and save labor but also enhances its corporate image, garnering widespread acclaim within the industry. This, in turn, solidifies existing customer relationships while attracting new ones. Automatic terminal crimping machines, also known as automatic wire stripping crimping machines, integrate functions such as feeding, cutting, and crimping. The wire rack for terminal machines is used in conjunction with terminal crimping machines, while the wire rack for...