Chain Terminal Crimp Issues? Get Back to Peak Performance!

Chain Terminal Crimp Issues? Get Back to Peak Performance!

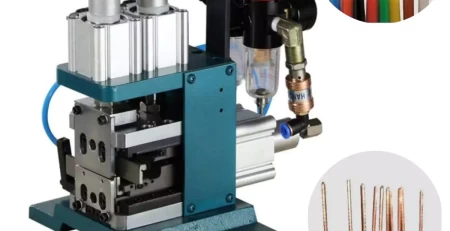

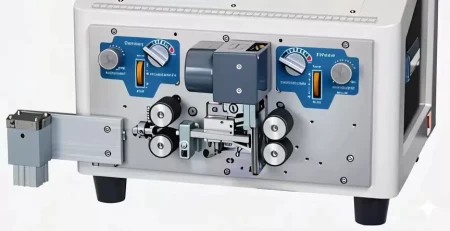

Automatic Chain Terminal Crimping Machines( ACTCMs) are fleetly getting an essential tool in electronic wiring harness product. Their effectiveness and delicacy make them a precious asset, but like any machine, they can encounter occasional interruptions. Then is a companion to relating and resolving some common ACTCM malfunctions

Power and Operation Issues

Problem Machine will not start or stops suddenly.

results

Check the basics corroborate that the machine receives the proper power input( generally 220V) and insure air pressure is at the recommended position( generally around 6KG).

product Complete? If the set total volume of creases has been reached, reset the counter. Power out and renew the machine.

concurrence Check Look for any obstructions within the machine that might jam cables or hamper moving corridor. insure all factors can move freely.

Connection evidence Double- check that all signal and power connections are secure and duly seated. Loose connections can disrupt machine operation.

Noise enterprises

Problem inordinate noise during ACTCM operation.

results

Lubricate Regularly Mild noise is normal during operation. still, inordinate noise may indicate increased disunion due to inadequate lubrication. Apply fresh slicking oil painting according to the manufacturer’s recommendations.

Strain it Up Loose screws can beget factors to joggle exorbitantly, leading to noise. Perform a routine tightening of all screws and fasteners to minimize unwanted climate.

Replace Worn corridor Over time, corridor can wear out, causing increased disunion and noise. However, consider replacing worn-out corridor with new bones , If lubrication and tensing do not resolve the issue.

Terminal Discovery Problems

Problem Poor terminal discovery or no seeing of outstations.

results

Alignment Check The optic fiber inquiry may be deranged, causing it to miss outstations. Acclimate the inquiry to insure it aligns duly with the path of outstations passing through the machine.

Distance Matters indecorous adaptation of the discovery distance between the terminal and the detector can lead to defective discovery. Re-adjust the distance according to the manufacturer’s instructions.

Sensor Health A damaged detector can compromise terminal discovery. check the detector for any visible damage. Consider replacing it if necessary.

Missing Terminal Check corroborate if the” missing terminal discovery” function is killed on the operating interface. However, the machine might not register missing outstations, If this function is impaired.

preventative conservation is crucial

To minimize ACTCM malfunctions, rehearsing good preventative conservation habits is pivotal. Then are some fresh tips

diurnal examination Perform a thorough visual examination and cleaning of the machine before each day’s operation. This helps identify implicit issues beforehand on.

Prompt Problem Addressing If you descry any abnormalities during operation, address the issue instantly to help it from raising and dismembering product.

slated conservation In addition to diurnal cleaning, follow the manufacturer’s recommended schedule for periodic conservation. This ensures your ACTCM continues to operate at peak performance.

By understanding these common problems and their results, you can keep your Automatic Chain Outstation Crimping Machine running easily, icing optimal productivity and effective line harness product.