Uneven Crimps? Fix Benchtop Terminating Machine Issues FAST!

Uneven Crimps? Fix Benchtop Terminating Machine Issues FAST!

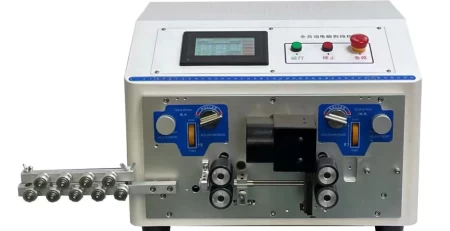

Occasionally, benchtop terminal crimping machines encounter colorful process- related faults during the product of outstations. When facing these issues in manufacturing, prompt results are essential to address the problems. Then, we epitomize some implicit problems that you may encounter, hoping to give you with some backing.

Inconsistent Cutting Length of Electronic Cables

Possible reasons include the line feeding wheel of the terminal machine being too tight or too loose. The result is to acclimate the straightener to unbend the line and insure smoothfeeding.However, replace the worn- eschewal slice blade, If necessary.

Varying Stripping Lengths

The line feeding wheel may be too tight or loose. Acclimate the gap between the two bus using the rolling wheel adaptation device to help line leveling or slipping. Also, acclimate the depth of the stripping blade to the applicable position to avoid damaging the bobby line while icing smooth stripping.

Failure to Start or Stop During Operation

Check for power input( 220V) and 6KG air pressure. insure that the set total volume has been reached. However, reset and renew after power out, If not. check for any line trap or inhibition in the machine’s moving corridor. Check for signal or power connection issues that may beget the machine to malfunction.

Uneven Bobby line Exposure After crimping

Check if the gun- type swing arm companion matches the line. insure that this benchtop crimper blade is aligned with the swing arm companion. Strain any loose supplementary pressure blocks. corroborate that the distance between the terminal machine and the automatic machine remains unchanged.

inordinate Noise from the Terminal Machine

Minor noise from the terminal machine is normal. still, inordinate noise may indicate increased disunion due to wear and tear between factors or corridor. Check for loose screws causing part vibration during operation.

Motor Failure in the Terminal Machine

Check the position of the clutch and insure the fuse isn’t burnt out.

nonstop Crimping by the Terminal Machine

check if the switch near the main shaft of the terminal machine is damaged or if any screws are loose. Check for any damage to the circuit board or bottom pedal of the terminal machine. insure that the selector spring isn’t detached or broken and has sufficient plainness.

Unresponsive Terminal Machine

Check if the power cord is connected duly and if there are any issues with the wiring. check the circuit board for damage. corroborate the functionality of each switch. Check if the bottom pedal is burnt out. Test the electromagnetic coil for captivation and signs of burning.

These are the implicit results to the eight types of faults bandied moment. instantly addressing faults encountered during terminal product demonstrates whether a company has a robust product operation system in place. We hope this composition is helpful. For further connector knowledge, please visit our website.