Boost Production: Dual-Head Wire Terminal Crimping Machines

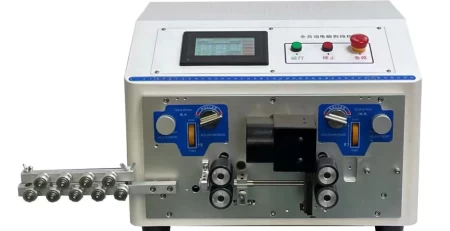

Demystifying the Dual-Head Terminal Crimping Machine: A Workhorse of Manufacturing

The world of manufacturing relies on a diverse range of equipment, and the dual-head terminal crimping machine plays a vital role in streamlining production processes. These machines automate the task of attaching terminals to wires, boosting efficiency and consistency. Let’s delve into the core components that orchestrate this operation.

The Three Pillars: Motion, Control, and Execution

A dual-head terminal crimping machine can be broken down into three fundamental parts: the motion system, the control system, and the execution system. The motion system, as the name suggests, governs the physical movement of the machine’s components, ensuring smooth and precise actions. The control system acts as the brain, sending specific commands based on programmed instructions. Finally, the execution system translates these commands into action, performing the actual crimping tasks with the required force and accuracy.

Decoding the Drive: Exploring Machine Types

Terminal machine manufacturers offer a variety of options, each catering to different needs and budgets. Here’s a breakdown of the three main categories based on their driving mechanisms:

Mechanical: This type utilizes belts and cams to drive the motion system. While offering an attractive price point, mechanical parts experience wear and tear over time, increasing maintenance needs and reducing their lifespan.

Stepper Motor: This option uses stepper motors for operation. They offer a more advanced design compared to mechanical models and are generally less expensive than true servo motors. However, domestically produced stepper motors can suffer from “lost steps,” compromising accuracy and potentially leading to inconsistent results. Unethical practices involve some manufacturers misrepresenting stepper motor machines as fully servo-driven or combining unknown servos with mechanical parts to mislead consumers.

Fully Servo: This category reigns supreme in terms of precision and durability. It employs a PLC (Programmable Logic Controller) to send signals to servo motors, ensuring precise control over movement. While the initial cost is higher, the combined benefits of accuracy and longevity make it a cost-effective solution in the long run.

The Unsung Heroes: Gearboxes

Gearboxes might seem like unassuming components, but they play a crucial role in the smooth operation of these machines. They offer several advantages:

Reduced Rotational Inertia: Gearboxes help control the machine’s speed by lowering the effective speed ratio, enabling precise starts, stops, and adjustments in movement.

Increased Torque: They act as torque amplifiers, essentially multiplying the input power from the motor, allowing for lower motor power requirements.

Motor Protection: Gearboxes shield the motor from overload damage. During operation, they absorb the brunt of the torque, safeguarding the motor from potential harm.

Improved Efficiency: By reducing the load on the motor, gearboxes enable smoother operation and lower energy consumption.

Motion Modules: Masters of Precision

Motion modules form the heart of the execution system. These marvels of engineering deliver several key functionalities:

Seamless Movement: They ensure smooth, gap-free movement for optimal performance and consistent results.

High Precision: Motion modules achieve exceptional levels of precision in their movements, crucial for accurate crimping of terminals.

Accurate Positioning: These components allow for precise positioning of the crimping head, ensuring consistent terminal attachment.

Robust Construction: Designed with rigidity in all directions, motion modules can handle heavy loads without compromising accuracy.

Long-lasting Performance: They are built to maintain their high precision even after extended use, minimizing downtime for maintenance.

High-Speed Capability: Motion modules enable the machine to operate efficiently at high speeds, boosting overall production throughput.

A Symphony of Efficiency

The dual-head terminal crimping machine exemplifies the power of well-coordinated engineering. Each component, from the motion system to the gearboxes and motion modules, plays a vital role in achieving consistent and efficient terminal crimping. This intricate interplay ensures the reliable production of high-quality electrical connections in numerous industries.

Find expert wire crimping machine technical resources on our specialized page.