Loop Cutting System: Sewing Precision Redefined

The Customizable Loop Cutting System: Revolutionize Your Sewing Workflow

Are you searching for a way to elevate your sewing workshops to new heights of efficiency and precision? Look no further than the Customizable Loop Cutting System. This innovative machine empowers you with unparalleled control and streamlines your belt loop cutting process.

Unveiling Ingenious Design:

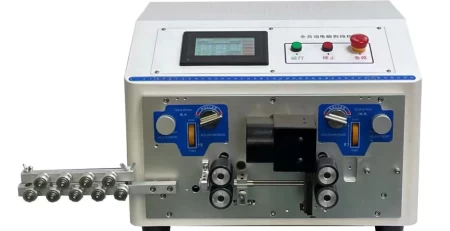

The heart of the Loop Cutting System lies in its groundbreaking design. Imagine a sturdy, symmetrical vertical mounting plate. This acts as the foundation for the system, providing unwavering stability. Mounted within the plate is a distinctive frame-shaped knife holder, cradling a sharp cutting knife horizontally. This holder, propelled by a sophisticated cam mechanism activated by a precise stepping motor, glides vertically with remarkable fluidity. Below, a horizontal cutter and an integrated belt platform further enhance the machine’s capabilities. To ensure smooth belt feeding, a powerful second stepping motor drives a feeding roller on the upper surface. All these elements are expertly orchestrated by a central controller, seamlessly harmonizing the operations of both stepping motors.

Benefits for Your Craft:

The Customizable Loop Cutting System unlocks a world of possibilities for your sewing workshops:

Unmatched Precision: Achieve flawless, consistent cuts every time. The meticulous design ensures pinpoint accuracy on every belt loop, eliminating the potential for human error.

Enhanced Efficiency: Streamline your workflow. The system’s automation eliminates time-consuming manual cutting, allowing you to focus on other aspects of your craft.

Customizable Control: Tailor the cutting process to your specific needs. The system offers adjustable settings for belt width and loop length, providing ultimate flexibility.

Reduced Waste: Minimize material waste. Precise cuts dramatically reduce the amount of unusable material scraps.

Elevated Work Quality: Impress your clients with impeccable craftsmanship. The system ensures professional-looking belt loops on every garment.

Optimizing Your Work Environment:

For optimal performance, consider these environmental factors:

Safe Power Supply: Ensure a reliable power supply within the recommended range (typically AC220-240V, or customized for your region) and proper grounding for safe operation.

Conducive Workspace: Maintain a dry, well-ventilated workspace with ample lighting for enhanced efficiency and operator comfort.

Corrosion-free Environment: Protect the machine’s longevity and functionality by avoiding environments with excessive moisture or dust that could cause corrosion.

By incorporating the Customizable Loop Cutting System into your sewing workshop, you can unlock a new level of precision, efficiency, and control. Embrace the future of crafting and elevate your creations to new heights.