Master Copper Stripping with a Manual Wire Stripping Machine

Mastering Copper Stripping: A Step-by-Step Guide to Operating the Manual Copper Wire Stripping Machine

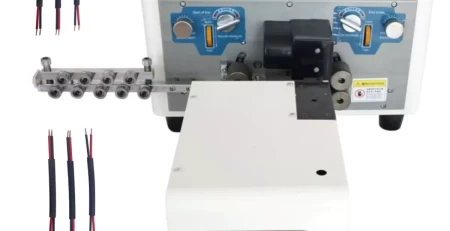

Wires can quickly become a tangled mess, hindering projects and deadlines. But fear not, for the manual copper wire stripping machine offers a compact and precise solution. Empowering You to Conquer Wire Processing: A Comprehensive Guide to Your Tabletop Champion.

Preparing for Action

Before unleashing your wire stripping prowess, ensure the machine is properly set up. Connect the air supply hose to a reliable source with 4.5-7kg/cm² pressure, such as a mini air compressor. Then, plug the machine into a standard 220V power outlet – your reliable companion is now ready.

Harnessing the Power

Unlike automated strippers, the manual machine requires a collaborative approach. The foot switch acts as your command center. A gentle tap activates the cylinder, the heart of the machine, allowing for precise control over the stripping action.

Fine-Tuning Your Weapon

Optimizing the machine for specific wire sizes is crucial. Locate the headless screw, which controls the position of the upper clamp block and the movement of the stripping blade. By loosening the nut on this screw, you can adjust the gap. Thicker wires require a wider gap for proper stripping, while thinner wires necessitate a tighter hold.

Achieving Precision

Once you’ve established the ideal gap, secure the headless screw back in place. Utilize the main cylinder to pull the wire, fine-tuning the stroke length with the adjustment screw. Need to adjust stripping speed? Simply modify the regulating valves – similar to adjusting gears on a bicycle.

Double the Efficiency

For enhanced efficiency, consider a double-cutter model, capable of simultaneously cutting and stripping wires. Follow the same calibration steps to optimize its performance.

Mastering the Details

A true master prioritizes detail. Maintain a 1.5mm gap between the cutter and the stripping blade to avoid damaging wires. Uneven stripping can occur if the gap is too wide. Additionally, the gaskets, which determine stripping length, deserve attention. Adjust their thickness for precise control, similar to adjusting the length of a sword.

A Versatile Champion

The manual copper wire stripping machine is a versatile tool for various tasks. It tackles complex multi-core cables with ease and neatly strips sheath and shield wires. This cost-effective solution offers both precision and energy efficiency. By embracing this tabletop warrior, you can unlock a new level of control and efficiency in your wire processing endeavors.

Find expert wire stripping machine technical resources on our specialized page.