Ultimate Shearing: Roll-to-Sheet Machine Benefits

Efficiency and Precision Redefined: The Roll-to-Sheet Slitter

Are you curious about the diverse applications of the Roll-to-Sheet Slitter, the ultimate Roll-to-Sheet Shearing Machine for Multi-Industries? Let’s dive in!

Introduction: The Unsung Hero of Material Processing

In the intricate world of industrial manufacturing, where precision meets productivity, roll-to-sheet slitting technology stands as a silent revolutionizer. From the seat belts that protect us on the road to the countless industrial applications we rarely consider, this technology forms the crucial first step in material transformation. Let’s explore how modern roll-to-sheet slitters are redefining precision across industries.

Section 1: The Anatomy of Safety – From Raw Rolls to Life-Saving Products

The journey of automotive safety begins long before seat belts secure passengers. Our machines process:

Core materials: Nylon, vinylon, silk, and specialized leathers

Reinforcement components: Carbon steel and aluminum alloy fittings

Protective coatings: Leather, light belt materials, vinylon, and rubber

Each roll represents potential – potential that our slitting technology unlocks with surgical precision. The transformation from bulk rolls to perfectly dimensioned sheets is where safety and quality truly begin.

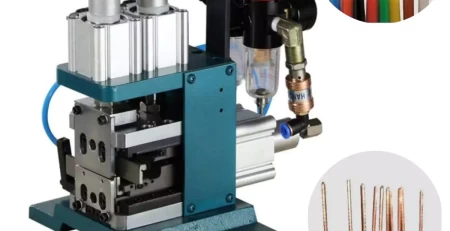

Section 2: Engineering Excellence – The Slitting Machine Breakdown

Our advanced Roll-to-Sheet Slitter incorporates:

Adaptive Cutting Systems:

Direct electric heating for clean, sealed-edge cuts

Pneumatic pressure control for material-specific precision

Thickness compensation for consistent results (0.1mm tolerance)

Intelligent Material Handling:

Automatic tension control (0-200N adjustable)

Multi-roller guidance systems

Real-time thickness monitoring

Operational Advantages:

Quick-change blade systems (30-second tool swaps)

24/7 continuous operation capability

Energy-efficient drive systems (30% power reduction vs. conventional models)

Section 3: Beyond Automotive – The Universal Solution

While seat belt production remains a core application, our technology serves diverse industries:

Textile & Apparel

Hook-and-loop tape processing (±0.2mm precision)

Elastic band slitting (up to 200m/min)

Decorative trim production

Industrial Manufacturing

Webbing and rope conversion

Plastic zipper processing

Composite material separation

Electronics & Specialized Applications

FPC (Flexible Printed Circuit) material preparation

Insulation membrane slitting

EMI shielding material processing

Section 4: The Precision Advantage – By the Numbers

Our slitting technology delivers measurable benefits:

99.8% cut accuracy rate

40% reduction in material waste

60% faster setup times compared to manual processing

30% increased throughput with automated systems

Section 5: Future-Proofing Your Production

The next generation of slitting technology incorporates:

AI-assisted tension control

Predictive maintenance systems

IoT-enabled performance monitoring

Sustainable processing options (low-energy modes, recyclable waste systems)

Conclusion: Precision as Your Competitive Edge

In today’s manufacturing landscape, the difference between adequate and exceptional often lies in your foundational processes. Our Roll-to-Sheet Slitter technology doesn’t just cut materials – it cuts costs, waste, and production bottlenecks while delivering unparalleled precision.

From automotive safety to industrial innovation, we’re redefining what’s possible in material conversion. The question isn’t whether you can benefit from this technology, but how soon you can implement it in your operations.

Call to Action:

Ready to transform your material processing? Contact our engineering team today for:

Customized solution consulting

Live demonstration sessions

ROI analysis for your specific application

Discover how precision slitting can become your newest competitive advantage. Share this technology with your procurement and production teams – the first cut is the most important one.