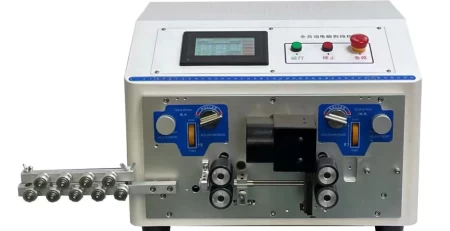

Microcomputer-Controlled Silicone Tube Cutter

Introduction: Revolutionizing Industrial Cutting with Smart Automation

In today’s fast-paced manufacturing environment, precision, efficiency, and versatility are critical. The microcomputer-controlled silicone rubber tube cutter represents a leap forward in automated cutting technology, combining intelligent control systems, adaptive feeding mechanisms, and multi-material compatibility to deliver unmatched performance.

This guide explores the cutting-edge features, industry applications, and future advancements of these machines, demonstrating why they are becoming indispensable across multiple sectors.

1. Advanced Features: Precision Engineered for Performance

1.1 Intelligent Microcomputer Control

The heart of the system lies in its programmable logic controller (PLC), which enables:

✔ Digital Parameter Adjustment – Set cutting length (0.1mm precision), batch quantities, and feed speed via an intuitive touchscreen.

✔ Memory Presets – Save configurations for different materials, reducing setup time.

✔ Error Detection – Automatic alerts for misalignment or feeding issues.

1.2 Adaptive Feeding Mechanisms

Unlike conventional cutters, this machine ensures smooth, damage-free material handling:

Dual-Roller Feeding System – Auto-adjusts pressure to prevent slippage or deformation.

Top-Needle Feeding Technology – Eliminates surface scratches on delicate materials (e.g., silicone tubes, PET films).

1.3 High-Precision Cutting Blade System

Laser-Calibrated Blades – Maintain sharpness for 50,000+ cuts.

Quick-Change Blade Design – Swap between straight, serrated, or rotary blades in seconds.

2. Material Compatibility & Industry Applications

2.1 Supported Materials

Material Type Example Uses

| Material Type | Example Uses |

|---|---|

| Silicone Rubber Tubes | Medical catheters, seals |

| Non-Woven Fabrics | PPE, filters |

| PET Films | Packaging, electronics |

| Adhesive Papers | Labels, tapes |

| Elastomeric Sheets | Gaskets, insulators |

2.2 Key Industry Applications

Medical Device Manufacturing

Cutting surgical tubing with ±0.05mm tolerance

Sterile-compatible models available

Automotive Components

Precision trimming of rubber hoses and gaskets

Electronics & Packaging

High-speed film cutting for displays and flexible circuits

Textiles & Consumer Goods

Automated fabric and adhesive label processing

3. Competitive Advantages: Why This Machine Stands Out

3.1 Operational Benefits

✅ 30% Faster Production vs. manual cutting

✅ Near-Zero Material Waste with optimized feeding

✅ Plug-and-Play Automation – Minimal operator training required

3.2 Cost Efficiency

ROI in <12 Months – Reduces labor costs by up to 60%

Energy-Saving Mode – Cuts power consumption by 20%

3.3 Market Potential

With demand rising in medical, automotive, and electronics sectors, these cutters are projected to grow at 8.5% CAGR through 2030 (Source: IndustryARC).

4. Future Innovations: Where Cutting Technology is Headed

4.1 Enhanced Precision (Next-Gen Models)

AI-Powered Vision Systems – Auto-detects material defects

Nanometer-Level Accuracy for microfabrication

4.2 Speed Advancements

High-Velocity Linear Actuators – Target: 500 cuts/minute

Predictive Maintenance – IoT sensors to preempt downtime

4.3 Sustainability Focus

Recyclable Blade Systems – Reducing tooling waste

Low-Friction Coatings – Extending component lifespan

5. Selecting the Right Machine: A Buyer’s Checklist

Feature Entry-Level Industrial-Grade

Cutting Precision ±0.1mm ±0.05mm

Max Speed 200 cuts/min 400 cuts/min

Material Width 50mm 100mm+

Smart Features Basic PLC AI + IoT Integration

Pro Tip: For medical or aerospace applications, prioritize ISO 13485-certified models with cleanroom compatibility.

Conclusion: Transforming Production with Smart Cutting

The microcomputer-controlled silicone rubber tube cutter is no longer just a tool—it’s a strategic asset. By delivering:

✔ Unmatched precision for quality-critical industries

✔ Scalable automation to meet rising demand

✔ Future-ready technology for tomorrow’s challenges

It’s time to upgrade your cutting process. [Contact Us] for a free material test-cut and see the difference firsthand.

Conclusion:

The microcomputer-controlled silicone rubber tube cutter presents a compelling solution for businesses seeking automated and efficient cutting solutions. Its diverse applications and numerous benefits make it a valuable asset for various industries. By focusing on continued technological development, manufacturers can further elevate the capabilities of this versatile machine.

Find expert silicone tube cutter technical resources on our specialized page.