Automatic 2AWG Wire Cutting Stripping Machine

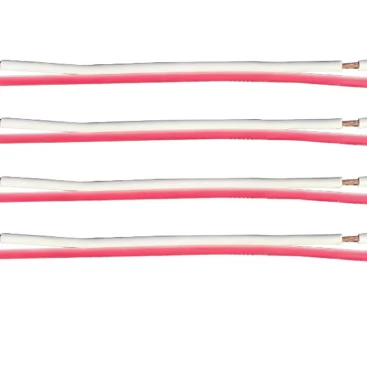

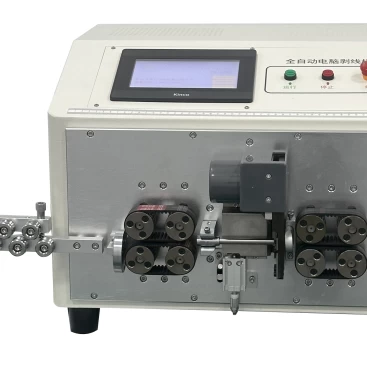

The FY-880D automatic computer wire stripping machine delivers high-precision processing with an accuracy of 0.01mm. It efficiently handles wire cutting, as well as single-end and double-end stripping, with a stripping length range of 0.01-150.00mm for the head and 0.01-70.00mm for the tail. Featuring a robust bi-directional ball screw system and a user-friendly 7-inch color touchscreen, it achieves a high production capacity of approximately 1,200-2,000 pieces per hour, ensuring reliable and efficient operation for your wire processing needs.

- Description

- Inquiry

Feature:

High Precision & Control: Achieves remarkable stripping accuracy of 0.01mm with a silent hybrid stepper motor and precision bi-directional ball screw blade holder.

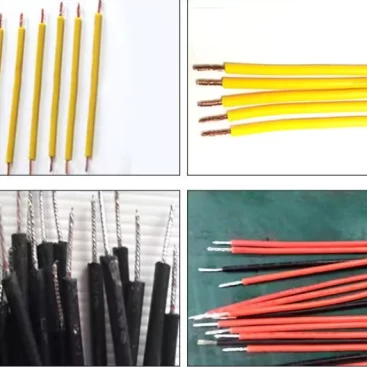

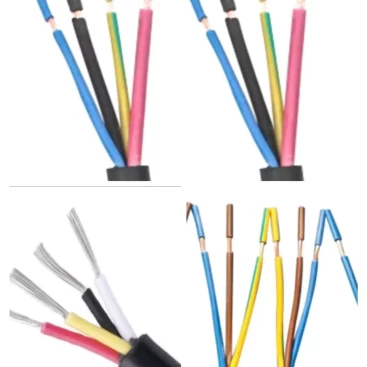

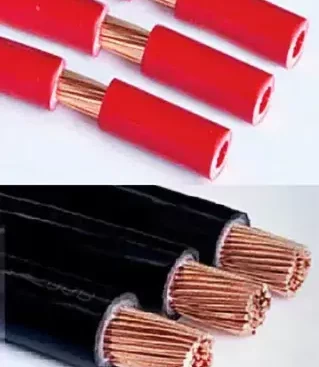

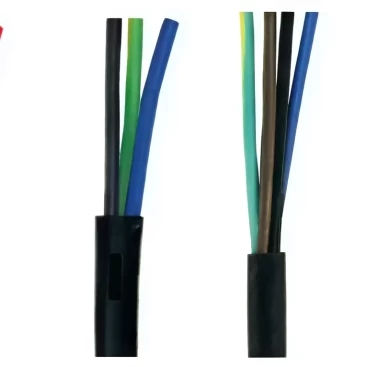

Versatile Processing Capacity: Handles a wide range of wires from 1-16mm in diameter, supporting various strip lengths (0.01-150mm head, 0.01-70mm tail) and complex mid-stripping.

Enhanced Efficiency & Output: Delivers high productivity with a speed of 40-50 m/min, yielding approximately 1,200-2,000 pieces per hour via an 8-wheel track feed system.

User-Friendly Operation: Features a 7-inch full-color touchscreen for intuitive control and allows easy storage of 100 different program presets (00-99) for quick job recall.

Robust & Reliable Construction: Built with durable components including high-speed steel/tungsten steel blades and a stable drive system with ball screws and gear racks for consistent performance.

Technical Parameters:

| Specification | Detail | Specification | Detail |

| Model Name | Automatic 2AWG Wire Cutting Stripping Machine | Core Wire Cutting Size | 1.0−35.0mm2 |

| Equipment Model | FY-880D | Cutting Diameter | 1−16mm |

| Input Power | AC220V50/60HZ | Conduit Diameter | 4−6−8−10−12−14−16 |

| Body Dimensions | L570mm×W550mm×H410mm | Cutting Length | 0.01mm−99999.99mm |

| Body Weight | 53kg | Strip Head Length | 0.01mm−150.00mm |

| Total Power | 1.8KW | Strip Tail Length | 0.01mm−70.00mm |

| Rated Power | 0.8KW | Middle Strip Segments | 16 Segments (Customizable) |

| Equipment Functions | Wire Cutting, Single-End Stripping, Both-Ends Stripping | Blade Material | High-Speed Steel/Tungsten Steel |

| Feeding Method | 8-Wheel Track/Caterpillar Type Feeding | Stripping Precision | Silent Hybrid Stepper Motor 0.01mm |

| Pressure Adjustment | Bi-directional Screw Computerized Adjustment | Driving Method | Hybrid Closed-Loop Stepping + Hybrid Open-Loop Stepping |

| Blade Holder Structure | Bi-directional Screw | Capacity/Hour | Approx. 1200−2000 Pieces |

| Conduit Oscillation/Swing | Electric | Feeding Speed | 40−50 meters/minute |

| Working Air Pressure | 0.5−0.8MPa | Program Storage | Serial Number 00−99 |

| Auxiliary Functions | Auto Wire In/Out, Timed Start, Jog Adjustment | Display Method | Full Touch 7-inch Color Display Screen |

| Transmission Structure | Precision Bi-directional Screw, Guide Sleeves, Gear and Rack |