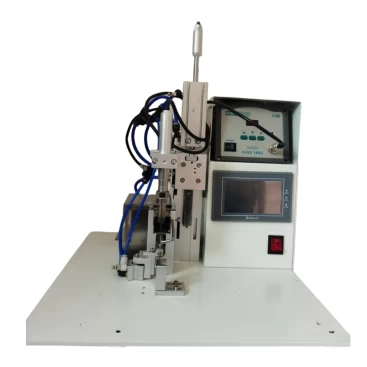

Automatic Wire Multi Cut Strip Twist Both-Ends Tinning Machine

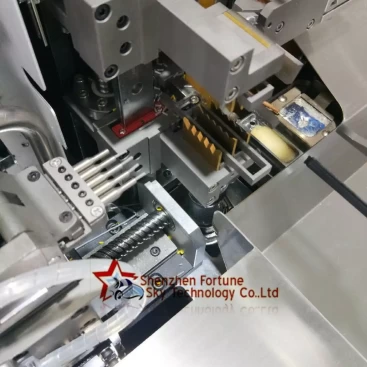

Introducing our advanced Automatic Multi-function Tinning Machine! Process 10 wires from AWG32 to AWG26 at once, with cutting, stripping, twisting, and tinning capabilities. Adjust tinning depth with a minimum cutting length of 8mm. Effortlessly handle single-end/double-end stripping, twisting, and precise tinning. Low-maintenance, unmanned operation, and automatic alerts after processing. Boost efficiency and productivity. Experience precision and versatility with this powerful tinning machine! Explore more now!

- Description

- Inquiry

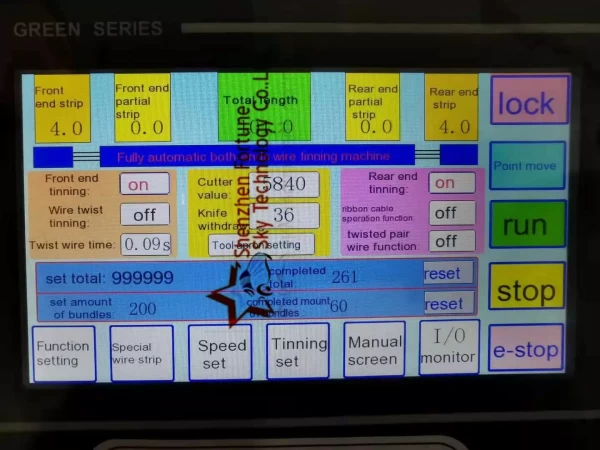

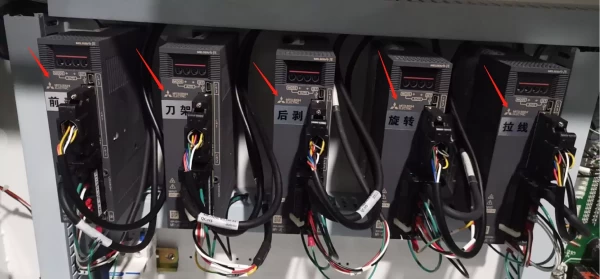

The Automatic Multi Twist Tin 10-Wire Cutting Stripping Machine is a compact, user-friendly, and versatile solution for high-volume wire processing. Its advanced features, including a digital touchscreen, high-speed servo drive, and simplified maintenance, make it an ideal choice for companies seeking efficiency and precision in wire processing tasks.

Feature:

Technical Parameters:

| Power supply | AC220V/5060HZ single-phase |

| Functions | Wire cutting, single-end stripping, double-end stripping, single-end twisting, double-end twisting, single-end twisting and tinning, double-end twisting and tinning. |

| Productivity | 16000-22000 pcs per hour (decided by the wire cutting length) AWG32-AWG26 cutting eight wires, AWG18 cutting four wires, production capacity varies according to wire type and size. |

| Appropriate Wire Range | hookup diameter 0.3mm-3.0mm (AWG32-AWG18) |

| Cutting length | the longest is 9999mm and the shortest is 8mm. |

| Stripping length | 0.0mm-10mm |

| Twisting length | 3.0mm-10mm |

| Tinning length | 1mm-10mm |

| Air pressure | 6kgf (clean and dry air is required) |

| Dimension | 670Wx840Lx1200H (mm) |

| Net Weight | about 310KG |

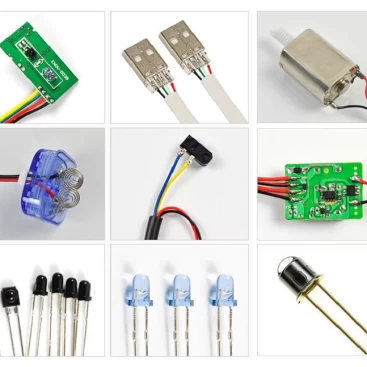

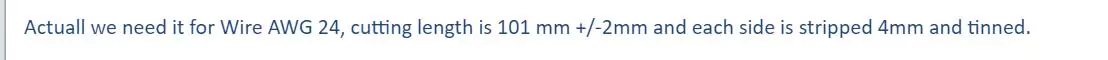

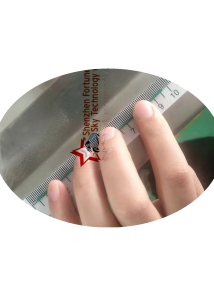

Client’s sampling:

[/vc_column_text]