Model: DG-01BS

Power supply: AC220V/50/60HZ single phase

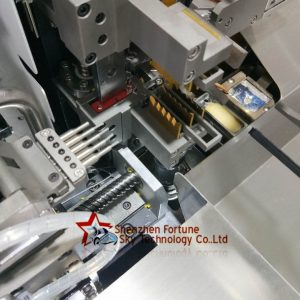

Function: wire cutting, single-end stripping, double-end stripping, single-end partial stripping, double-end partial stripping, double-end twisting, single-end tinning, double-ended tinning, can be customized for ribbon cable.

Wire processing range: AWG# 32- AWG#18, wire diameter from 0.6MM to 3.2MM

Productivity: 7000-13000 pcs/hour, (depending on the wire)

Cutting length: 10-600MM (special length can be set)

Cutting accuracy: 0.2±0.02*L (length)

Stripping length: 0-7MM (customized above 7mm)

Twisted line length: 3-7MM

Dip tin length: 0.5-7MM

Air pressure: 5-6 kg

Machine size: 1210*770*1370 (without protrusions)

Body weight: about 400kg

Main component configuration

The machine uses Hechuan servo motor: (6 sets)

Pneumatic components: solenoid valve + cylinder + air pipe (SMC)

Air pressure detection: SMC

Screw guide: Taiwan HIWIN

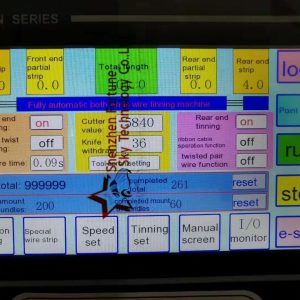

Controller: US RAM computer control system

Color touch screen: KINCO

Full CNC debugging: knife size, stripping length, tinning depth