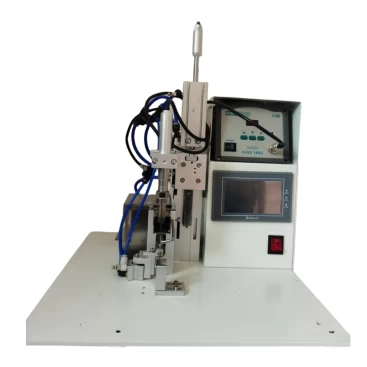

Automatic Wire Cutting Stripping Twisting Linear Feed Crimping and Tinning Machine

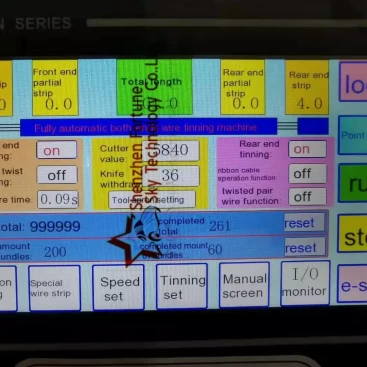

This machine features a user-friendly Chinese/English touch screen for easy operation. It offers quick and efficient process changes, high precision, and speed. Equipped with 6 sets of servo motors/drivers, Taiwan AirTAC pneumatic components, and CPC/Hiwin ball screw guides, this machine delivers superior performance. The Beckhoff color touch screen allows for full computer numerical control of blade size, cutting length, and more, ensuring precise customization.

- Description

- Inquiry

Machine Features:

- User-friendly Chinese touch screen operation;

- Quick and efficient changeover of processes and materials, high precision and speed, easy maintenance;

- Servo control: 6 sets of servo motors/drivers;

- Pneumatic components: Solenoid valve + cylinder (Taiwan AirTAC);

- Ball screw guide: Taiwan CPC/Hiwin;

- Color touch screen: Beckhoff (Taiwan);

- Full computer numerical control adjustment: Blade size, cutting length, stripping length, flux dipping depth, tinning depth, all realized through digital touch screen operation;

Technical Parameters:

| Project Name | Technical Parameters |

| Model No. | HWN-8316 |

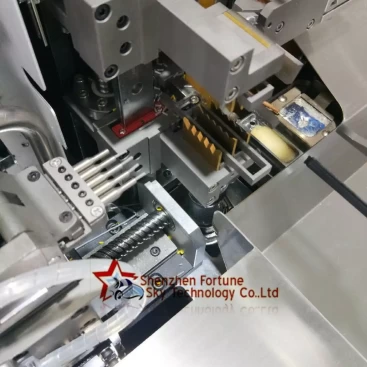

| Function | Wire cutting, single-end stripping, double-end stripping, single-head crimping, single-end twisting, single-end tinning (can be turned on and off). |

| Cutting length | 35mm-1000mm (longer wire can be customized) |

| Cutting accuracy | 0.2±0.02L |

| Stripping length | 1mm-10mm |

| Wire diameter | 0.6mm-3.5mm |

| Tinning length | 1mm-10mm |

| Twisting length | 2mm-10mm |

| Universal wire diameter | AWG#16-AWG#32 |

| Crimping pressure | 2.0T terminal machine |

| Working speed | Single wire with outer diameter of 1-2MM and length of 500MM, capacity is about |

| Air pressure | 0.5-0.7MPA |

| Detection device | Crimping detection, missing wire detection, wire knotting, presence of terminal |

| Blade material | High-speed steel |

| Machine size | L180xW98xH160CM |

| Machine weight | 290KG |

| Auxiliary device | Terminal waste paper winding device |

| Power supply | AC220 Single phase 8A |