IPEX Terminal Coaxial Cable Crimping Machine

Master precision crimps for 1-PX connectors! This specialized machine delivers quiet, energy-efficient operation for effortless riveting and forming of 1-PX series terminals. The user-friendly design ensures easy maintenance and control, while the versatile functionality allows you to tackle various connector needs. Take your coaxial cable assembly to the next level!

- Description

- Inquiry

Description

Features:

1.) Quiet Operation: The motor activates only when you step on the foot pedal, minimizing motor noise and the loud sound from mechanical clutch and electromagnetic collisions.

2.) Maintenance-Free Longevity: By replacing traditional machine clutches or electromagnetic clutches with electrical control, we’ve eliminated hard contact between components, reducing wear. Additionally, all transmission parts undergo hydrogen permeation treatment to enhance strength and wear resistance. The machine is powered by a precision reducer and motor, ensuring long-term reliability.

3.) Energy Efficiency: Our design greatly reduces energy consumption. Energy consumption for typical operations is 10x250A = 2.5KW/H, while the machine’s energy consumption is calculated as 40000×0.2 (seconds/pcs) /3600x250W=0.556KW/H. Compared to single-machine operation, our system saves nearly 2KW of energy per shift.

4.) Easy PLC Control: The PLC control system makes operation simple, with easy switching between manual and automatic modes.

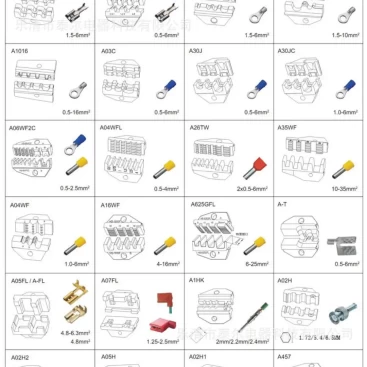

5.) Versatile Application: Ideal for riveting and forming IPEX series precision connector terminals, this machine is also suitable for crimping other related connector terminals.

| Function | PBF-IPEX terminal crimping machine |

| Production | 1500-1800 pcs/hour |

| Appropriate Wire Gauge | <=2.5 mm2 |

| Applicable terminal | 0.81/1.13/1.32/1.37/1.78mm |

| Power supply | AC110-220V,50-60Hz |

| Noise | <70DB(A) |

| Air source | 0.5-0.7 Mpa (5-7 bar) |

| Stroke | 30mm |

| Dimension | 350x260x200mm |

| Net Weight | 8 KG |

| Application | This machine is dedicated to riveting and forming 1-PX series precision connector terminals, and it also applies to the molding of other related connector terminals. |