Fully Automatic Five Wires Cut Strip Tin Linear Feeding Double-Ends Terminal Crimping Machine

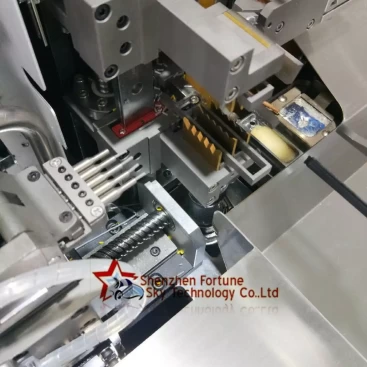

Experience the versatility of the HWN-85A. This automated machine handles various wire processing tasks, including cutting, stripping, and crimping, with exceptional precision. Its intuitive touchscreen interface and robust design make it a reliable and efficient solution for your production needs.

- Description

- Inquiry

Machine Features:

Computer touchscreen Chinese operation menu, easy to learn and use.

Quick and efficient replacement of processes and materials, high precision,high speed,

and easy maintenance.

The machine adopts servo control: 7 sets of servo motors/drives (Huachuang).

Pneumatic components: Solenoid valve +cylinder (Xingchen).

Ball screw guide:Taiwan CPC.

Color touchscreen: Botek(Taiwan).

Full computer numerical control debugging: Knife size, cutting line length, stripping length,

flux dipping depth, tinning depth.

| Parameter | Description |

| Model | HWN-85A |

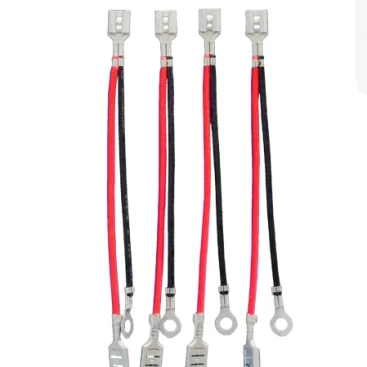

| Product | Single-head crimping, double-head crimping, one-end crimping and one-end stripping |

| Function | Applicable: Terminal PH/XH/EH/ZH/CSN/SM different terminals, mold replacement required. Cutting, single-end stripping, double-end stripping, double-end semi-stripping, double-end crimping, single-end crimping, single-end finning (tinning function can be removed as client’s demand) |

| Dimensions | Length 183cm* Width 120cm*Height 165cm |

| Weight | Approximately 550kg |

| Power Supply | Single-phase AC 220V±15%/50Hz |

| Total Power | 1000W |

| Crimping Force | 2T |

| Working Air Pressure | 0.4mpa-0.8mpa, dry air source are required |

| Required Space | 5 square meters |

| Crimping Efficiency | 5000 pieces/hour (calculated based on 100mm length) |

| Blade Replacement | Replace the crimping die |

| Cutting Length | 45mm-800mm (customizable) |

| Stripping Length | 1-6mm (customizable) |

| Applicable Wire | AWG#26-AWG#18 electronic wire |