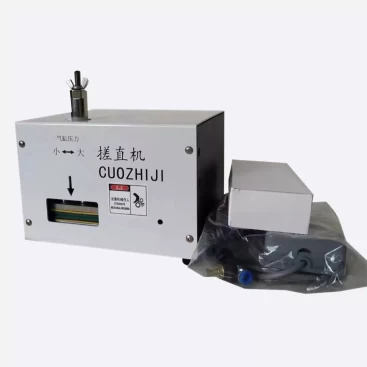

Automatic Wire Threading Stripping Ferrule Crimping Machine

Effortless wire harness assembly! This all-in-one machine automates stripping, threading, and crimping for unmatched speed and precision. The intuitive interface and robust design make it perfect for high-volume production, boosting your efficiency and saving you time.

- Description

- Inquiry

Technical Parameters:

Product Name: Automatic Wire Threading Stripping Ferrule Crimping Machine

Rated Power Supply: AC220V 50/60Hz

Air Source: 0.6-0.8Mpa (The pressure of the dry air inlet must be maintained at no less than 0.6 MPa.)

Control Method: Human-machine interface,Electronic control,Pneumatic control

Running Way: Automatic trigger,Manual operation

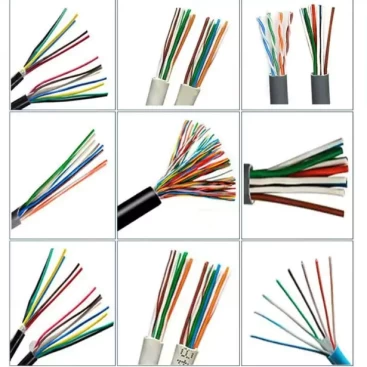

Suitable wires: Suitable for BVR wires 0.3, 0.5, 0.75, 1.0, 1.5, 2.5, 4.0, 6.0 square mm

Net Weight: around 60kg

Dimension: 350x450x400mm

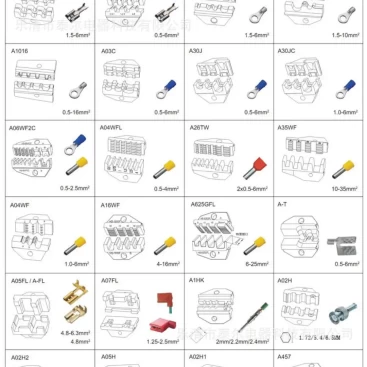

Terminal Specifications: Terminal insulation length is within 7.5mm,Conductor length is within 12mm.

Crimping Shapes: Quadrilateral, Hexagon custom shapes available

To replace the product, follow these steps: manually replace the corresponding fixtures, adjust the vibration plate, and perform the electric memory adjustment.

Production Capacity: 2.5 seconds per wire (considered a single machine cycle)

The machine performs two inspection items: terminal presence detection and right-side safety door open detection.

The operating temperature of the machine is 10-25 degrees Celsius, so it should be used in a room where the temperature is within this range.

The operating humidity of the machine is 30-80%RH, so it should be used in a room where the humidity level is within this range and there is no condensation.